Understanding the amp usage of a circular saw is crucial for both efficiency and safety. When it comes to power tools, including circular saws, knowing the amp rating helps users determine the electrical current required for optimal performance. This knowledge allows users to choose the appropriate power supply, preventing potential issues such as underpowered operation or overloading circuits.

Optimizing power consumption plays a vital role in ensuring efficiency. By understanding the amp usage of a circular saw, users can select a power source that matches the tool’s requirements, resulting in smoother operation and consistent cutting power. This not only improves the overall performance but also prolongs the lifespan of the saw by reducing the risk of overheating or damage caused by inadequate power supply.

Safety is another crucial aspect linked to understanding amp usage. A circular saw that is not supplied with the correct amperage can pose safety risks. Insufficient power may lead to the saw struggling to perform, increasing the chances of kickback or improper cutting techniques. On the other hand, using a power supply with higher amperage than necessary can overload the saw and potentially damage its motor or other components.

To ensure both efficiency and safety, it is essential to have a clear understanding of the amp usage of a circular saw. In the following sections, we will delve deeper into the significance of amps, explore the impact of amp ratings on circular saw performance, and provide valuable tips to help you optimize power consumption while using a circular saw.

Understanding Amps and Their Significance

Amps, short for amperes, are a unit of measurement used to quantify the amount of electrical current flowing through a circuit. They represent the rate at which electric charge moves through a conductor. In the context of power tools, including circular saws, amps indicate the amount of current required for proper operation.

Electrical current is analogous to the flow of water through a pipe. Amps, in this analogy, are equivalent to the volume of water flowing through the pipe per unit of time. The higher the amperage, the greater the flow of electrical current.

Knowing the amp requirements of power tools, such as circular saws, is of paramount importance. Each power tool has a specific amp rating, which indicates the amount of electrical current it needs to operate efficiently. If the power supply cannot deliver the required amps, the tool may underperform, lacking cutting power and speed. In extreme cases, it may not function at all.

Conversely, if the power supply delivers an excessive amount of amps beyond what the tool requires, it can lead to overloading. This can cause the tool to overheat, leading to premature wear and tear, motor damage, or even pose a safety hazard. Therefore, it is crucial to have a clear understanding of the amp requirements of a circular saw to ensure its optimal performance and longevity.

By knowing the amp rating of a circular saw, you can select the appropriate power source, such as a suitable electrical outlet or battery pack for corded and cordless saws, respectively. This ensures a proper match between the tool and the power supply, enabling smooth and efficient operation. Additionally, understanding amp requirements allows you to avoid potential safety risks associated with using inadequate or excessive power, promoting a safe working environment.

In the following sections, we will explore how amp ratings impact the performance of circular saws, methods to determine the amp rating of a specific saw, and factors that can influence amp usage.

How Amps Impact Circular Saw Performance

The amp rating of a circular saw has a direct impact on its cutting power and overall performance. Understanding this relationship can help users make informed decisions when selecting a saw and optimizing its usage.

The relationship between amps and cutting power can be understood by considering the electrical current as the energy that drives the saw’s motor. The motor, in turn, powers the rotation of the saw blade, enabling it to cut through various materials. As the amp rating increases, so does the amount of electrical current flowing through the motor, resulting in a higher power output.

Higher amp ratings in a circular saw can enhance cutting speed and efficiency in several ways. Firstly, increased amperage provides more power to the motor, allowing it to drive the saw blade with greater force. This extra power translates into faster cutting speeds, enabling users to complete their tasks more quickly.

Moreover, a circular saw with a higher amp rating tends to have a stronger and more robust motor. This increased motor strength enables the blade to maintain a consistent cutting speed, even when working with denser or tougher materials. It reduces the risk of the blade slowing down or stalling during demanding cuts, ensuring smoother and more efficient cutting operations.

In addition to improved cutting power and speed, higher amp ratings often correspond to enhanced overall performance. Circular saws with higher amps are typically designed to handle heavy-duty tasks and can withstand prolonged use without overheating or experiencing motor strain. They provide a reliable and consistent cutting experience, even in challenging cutting conditions.

It is important to note that while higher amp ratings can offer advantages in terms of cutting power and efficiency, it is equally essential to consider the specific requirements of the intended cutting tasks. Not all applications demand the highest amp-rated saws, and selecting a saw with excessive amperage for light-duty tasks may not yield significant benefits. Understanding the requirements of your specific cutting projects and balancing them with the appropriate amp rating will help you achieve optimal performance and efficiency.

In the upcoming sections, we will explore methods for determining the amp rating of a circular saw and discuss the average amp ranges for different types of saws.

Determining the Amp Rating of a Circular Saw

To determine the amp rating of a circular saw, you can follow these steps:

- Check the Saw Body: Examine the circular saw itself for any labeling or markings that indicate the amp rating. Manufacturers often include this information on the saw body, either on the main body or near the handle. Look for labels or tags that display the amp rating prominently.

- Consult the Manual: If you don’t find the amp rating on the saw body, refer to the user manual that came with the circular saw. The manual usually contains detailed specifications, including the amp rating. Look for a section that provides technical information or specifications for the saw model.

- Online Resources: If you no longer have the manual or cannot find the amp rating on the saw itself, consider visiting the manufacturer’s website. Many manufacturers provide product documentation, including user manuals and specifications, which can be downloaded or accessed online. Search for the specific model of your circular saw and look for the amp rating information within the provided documentation.

Interpreting the amp rating of a circular saw is crucial to understanding its power requirements and implications. Here’s some guidance on interpreting the amp rating and its significance:

- Amp Rating Range: The amp rating of circular saws can vary depending on the model, type (corded or cordless), and intended usage. Typically, amp ratings for circular saws range from around 10 to 15 amps for corded models and vary for cordless models based on the battery voltage.

- Power Supply Considerations: Understanding the amp rating helps you ensure that the power supply, such as an electrical outlet or battery pack, can provide the required current. If the amp rating of the saw exceeds the capacity of the power supply, it may not deliver adequate power, leading to suboptimal performance or even potential damage.

- Match the Task: Consider the type of cutting tasks you’ll be performing with the circular saw. Heavy-duty tasks, such as cutting through thick or dense materials, may benefit from higher amp ratings, as they provide more cutting power and speed. Lighter tasks may not require the maximum amp rating and can be adequately handled by lower amp-rated models.

- Safety Precautions: Using a power supply that matches the amp rating of the circular saw is crucial for safety. It helps prevent overheating, motor strain, and potential hazards. Exceeding the recommended amp rating can cause the tool to overload or malfunction, posing a safety risk.

By understanding how to locate the amp rating and interpreting its implications, you can make informed decisions about the power supply and select the appropriate circular saw for your cutting needs. In the following sections, we will delve into the average amp ranges for different types of circular saws and explore the factors that can affect amp usage.

Average Amp Range for Circular Saws

When considering the amp range for circular saws, it’s important to differentiate between corded and cordless models as their power sources and designs can impact their amp ratings. While specific models may vary, the following are general guidelines for the average amp range:

- Corded Circular Saws: Corded circular saws typically have higher amp ratings compared to their cordless counterparts. On average, corded circular saws fall within the range of 10 to 15 amps. This range provides ample power for various cutting tasks, including heavy-duty applications.

- Cordless Circular Saws: Cordless circular saws are powered by rechargeable batteries, which influences their amp ratings. The amp range for cordless circular saws varies based on the voltage of the battery pack. Common battery voltages for cordless circular saws are 18V, 20V, and 24V. The corresponding amp ratings for these voltages typically range from 4 to 6 amps.

It’s important to note that while cordless circular saws generally have lower amp ratings compared to corded ones, advancements in battery technology have led to improved performance and efficiency. Manufacturers are continuously developing higher voltage battery systems that can provide ample power for demanding cutting tasks.

When discussing average amp ratings for circular saws, it can be helpful to refer to statistical data or studies. While specific data may vary based on the source and study parameters, the following examples provide a general idea of average amp ratings:

- A study conducted by a power tool review website analyzed various corded circular saws and found that the average amp rating among the models reviewed was approximately 12 amps. This suggests that 12 amps is a commonly observed amp rating for corded circular saws.

- Another survey conducted among professional carpenters indicated that the majority of cordless circular saws used on construction sites had amp ratings ranging from 4 to 6 amps. This finding aligns with the general amp range for cordless circular saws mentioned earlier.

These statistics and studies serve as indicators of the typical amp ratings for different types of circular saws. However, it’s important to consult specific product specifications and manufacturer information for accurate and up-to-date amp ratings when considering a particular circular saw model.

In the subsequent sections, we will explore the factors that can affect amp usage in circular saws, which can further guide users in optimizing their power consumption.

Factors Affecting Amp Usage

The amp usage of a circular saw can be influenced by various factors. Understanding these factors is essential for optimizing power consumption and ensuring efficient operation. Here are some key factors that can impact amp usage:

- Blade Size and Type: The size and type of blade used in a circular saw can affect its amp usage. Larger blades generally require more power to rotate and cut through materials. Additionally, different blade types, such as ripping blades or fine-tooth blades, have varying cutting characteristics, which can impact the amp draw of the saw.

- Material Being Cut: The type and density of the material being cut can significantly influence amp usage. Harder and denser materials, such as hardwood or thick metal, require more cutting power and may result in higher amp draw. Conversely, cutting softer or less dense materials may require less power and result in lower amp usage.

- Cutting Techniques: The way in which the circular saw is used can also affect amp usage. For example, aggressive cutting techniques that put excessive pressure on the blade or force the saw to work harder can increase amp draw. Conversely, employing smooth and controlled cutting techniques can help reduce amp usage.

- Saw Motor Efficiency: The efficiency of the circular saw’s motor plays a role in amp usage. Motors that are designed to be more efficient can convert electrical power into mechanical power more effectively, resulting in lower amp draw for a given cutting task. High-quality motors with efficient designs can contribute to overall power optimization.

It’s important to note that while these factors can influence amp usage, their impact may vary depending on the specific saw model and design. Manufacturers often provide guidelines and recommendations for optimal amp usage based on these factors in the saw’s user manual or product specifications.

By considering these factors and making conscious choices, users can optimize their amp usage with a circular saw. This not only helps to minimize power consumption but also ensures efficient cutting performance and extends the life of the tool. In the next sections, we will discuss the importance of using the correct amperage and provide practical tips for efficient amp usage with a circular saw.

Importance of Using the Correct Amperage

Using the correct amperage, matching the power supply to the amp rating of a circular saw, is of utmost importance. Failure to do so can have significant consequences that affect both safety and performance. Here are some potential risks and drawbacks associated with using an inadequate power supply:

- Safety Risks: When a circular saw is not supplied with the correct amperage, safety risks can arise. Insufficient power supply may cause the saw to operate at a reduced capacity, leading to inefficient cutting and potentially causing the blade to get stuck or bind in the material. This can result in kickback, where the saw jerks back uncontrollably towards the user, posing a severe injury risk. Inadequate power can also lead to overheating of the motor, potentially causing the tool to malfunction or even start a fire.

- Decreased Performance: Using an inadequate power supply can severely impact the performance of a circular saw. Insufficient amperage can result in reduced cutting power and slower cutting speeds. The saw may struggle to make clean cuts, resulting in uneven edges or requiring multiple passes to complete a cut. This not only affects the efficiency of work but also increases the chances of errors and inaccuracies in the cutting process.

- Motor Strain and Damage: Mismatched amperage can put excessive strain on the motor of the circular saw. When a saw is underpowered, the motor may have to work harder to maintain cutting speed, resulting in increased wear and tear. Over time, this can lead to motor damage, reduced lifespan of the tool, and the need for costly repairs or replacement.

- Inefficient Energy Consumption: Using a power supply with higher amperage than necessary for a circular saw wastes energy. The excess electrical current drawn from the power supply is not effectively utilized by the tool and is essentially wasted. This inefficient energy consumption can have environmental and cost implications, especially for extended periods of use.

To mitigate these risks and ensure optimal performance, it is crucial to match the amp rating of a circular saw with the correct power supply. Following the manufacturer’s recommendations regarding amp requirements and using appropriate electrical outlets or battery packs will promote both safety and efficiency during operation.

In the next sections, we will provide practical tips for efficient amp usage with a circular saw, including selecting the right blade and employing proper cutting techniques.

Tips for Efficient Amp Usage

To optimize amp usage while using a circular saw and ensure efficient operation, consider the following practical tips:

- Choosing the Right Blade for the Task: Selecting the appropriate blade for your cutting task can help reduce amp usage. Use blades with the correct teeth configuration, size, and type for the material you are cutting. A blade designed for the specific task will require less effort from the saw, resulting in lower amp draw.

- Using the Appropriate Speed Settings: Most circular saws offer variable speed settings. Adjusting the speed to match the requirements of the material being cut can help optimize amp usage. Higher speeds may be suitable for softer materials, while slower speeds may be more efficient for denser or tougher materials. Experiment with different speed settings to find the optimal balance between cutting power and amp usage.

- Properly Maintaining the Saw and its Components: Regular maintenance of the circular saw is essential for efficient amp usage. Keep the blade sharp and clean to minimize friction and strain on the motor. Check and tighten any loose components to ensure stable and efficient operation. Lubricate moving parts as recommended by the manufacturer to reduce friction and promote smooth cutting.

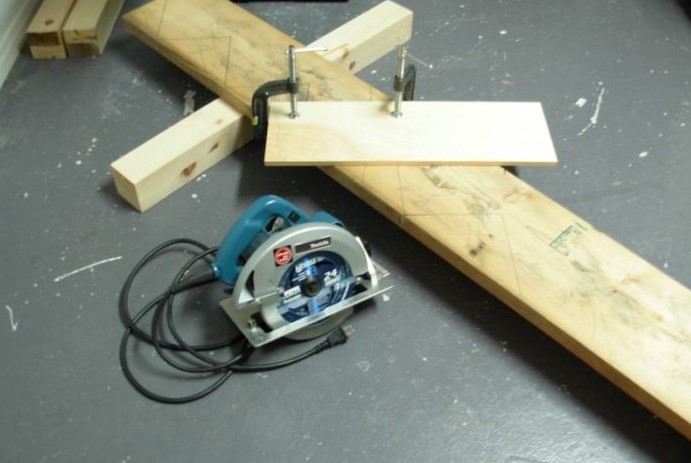

- Supportive Work Surface: Ensure the work surface is stable and adequately supports the material being cut. A stable work surface minimizes vibrations and reduces the strain on the saw, resulting in more efficient cutting and lower amp usage. Consider using clamps or other support mechanisms to secure the workpiece, especially for larger or heavier materials.

- Controlled Cutting Techniques: Practice proper cutting techniques to optimize amp usage. Apply consistent and controlled pressure while guiding the saw through the cut. Let the blade do the work, avoiding excessive force or pushing. Smooth and controlled cuts reduce amp draw and improve overall cutting efficiency.

- Avoid Overloading the Saw: Avoid overloading the saw by forcing it to cut beyond its capacity. This can lead to increased amp usage, motor strain, and potential damage. If the saw begins to bog down or slow significantly during a cut, release the trigger and reassess the cutting technique or consider using a more appropriate blade for the task.

By implementing these tips, you can optimize amp usage with your circular saw, ensuring efficient cutting performance while reducing the strain on the motor and power supply. This not only promotes a longer lifespan for your saw but also enhances safety and helps achieve precise and clean cuts.

In the following sections, we will discuss safety precautions and best practices when operating a circular saw, as well as address frequently asked questions related to amp usage in circular saws.

Safety Precautions and Best Practices

When operating a circular saw, it is essential to prioritize safety to prevent accidents and injuries. Here are some general safety measures and best practices to follow:

- Wearing Appropriate Protective Gear: Always wear appropriate personal protective equipment (PPE) when using a circular saw. This includes safety goggles or glasses to protect your eyes from flying debris, ear protection to reduce noise exposure, a dust mask to prevent inhalation of dust particles, and sturdy work gloves to protect your hands from cuts or scrapes. Additionally, consider wearing a long-sleeved shirt, long pants, and closed-toe shoes for added protection.

- Maintaining a Clean and Well-Lit Work Area: Ensure your work area is clean and well-organized before using a circular saw. Remove any obstacles, debris, or tripping hazards that could interfere with safe operation. Adequate lighting is crucial to maintain visibility and prevent accidents. Make sure the area is well-lit, or consider using additional task lighting if necessary.

- Following Proper Handling and Cutting Techniques: Adhere to proper handling techniques to ensure safe and effective use of the circular saw. Hold the saw firmly with both hands, keeping your fingers away from the blade and the cutting line. Avoid reaching over the saw or crossing your arms while cutting. Use a steady and controlled grip to guide the saw through the material, maintaining a safe distance from your body.

- Using Safety Features: Familiarize yourself with the safety features of your circular saw and ensure they are in proper working condition. These may include blade guards, riving knives, and safety switches. Do not remove or disable any safety mechanisms provided by the manufacturer.

- Unplugging or Locking the Saw: When not in use or during blade changes, unplug corded circular saws or remove the battery pack from cordless saws to prevent accidental starts. If your saw has a lockout feature, engage it to prevent accidental activation of the trigger.

- Avoiding Freehand Cuts: Whenever possible, use guides, clamps, or a straightedge to guide the saw and maintain accurate cuts. Freehand cuts can be more challenging to control and increase the risk of accidents.

- Practicing Tool Maintenance: Regularly inspect your circular saw for any damage or signs of wear. Follow the manufacturer’s recommendations for maintenance, such as blade changes, lubrication, and adjustment of components. Properly maintained tools ensure safe and efficient operation.

Remember, these are general safety precautions, and it is important to consult the user manual and follow the specific guidelines provided by the manufacturer of your circular saw.

By incorporating these safety measures and best practices, you can significantly reduce the risk of accidents and injuries while operating a circular saw.

In the next section, we will address frequently asked questions related to amp usage in circular saws, providing detailed answers and explanations.

FAQs about Circular Saw Amp Usage

Q. Can I use a circular saw with a lower amp rating than recommended?

Ans. It is generally not recommended to use a circular saw with a lower amp rating than what is recommended by the manufacturer. Using a lower amp-rated saw may result in insufficient cutting power, slower cutting speeds, and potential strain on the motor. It is best to match the amp rating to the recommended specifications for optimal performance and safety.

Q. Can I use a circular saw with a higher amp rating than recommended?

Ans. While it is possible to use a circular saw with a higher amp rating than recommended, it is important to exercise caution. Using a higher amp-rated saw does not provide any significant advantages unless you are performing heavy-duty cutting tasks. However, using a significantly higher amp-rated saw can overload the power supply, potentially damaging the tool and posing safety risks. It is generally recommended to use a saw that matches the recommended amp rating for your specific cutting needs.

Q. How can I determine if the power supply can handle the amp rating of my circular saw?

Ans. To ensure the power supply can handle the amp rating of your circular saw, check the ampacity (ampere capacity) of the electrical outlet or the compatibility of the battery pack for cordless saws. The ampacity of the outlet should be equal to or greater than the amp rating of the saw. For cordless saws, ensure that the battery pack has the appropriate amp rating and voltage recommended by the manufacturer.

Q. Can using an inadequate power supply damage the circular saw?

Ans. Yes, using an inadequate power supply can potentially damage the circular saw. If the power supply cannot provide the required amps, it can strain the motor and lead to overheating. Overloading the saw with excessive amps can also cause motor damage and other component failures. It is important to match the power supply to the amp rating specified by the manufacturer to ensure safe and optimal operation.

Q. What should I do if my circular saw keeps tripping the circuit breaker?

Ans. If your circular saw repeatedly trips the circuit breaker, it is an indication that it is drawing more amps than the circuit can handle. This can occur if the amp rating of the saw exceeds the circuit’s capacity. To resolve this issue, consider using a circuit with a higher amp rating or redistributing the load on different circuits. If the problem persists, consult an electrician to ensure the electrical system can support the power requirements of your circular saw.

Q. Can I use an extension cord with a circular saw?

Ans. Yes, you can use an extension cord with a circular saw, but it is important to choose the right one. Select an extension cord that is rated for the amp draw of your circular saw. Use a heavy-duty extension cord with a sufficient wire gauge to prevent voltage drop and ensure adequate power supply. Refer to the manufacturer’s guidelines for the recommended extension cord specifications.

By addressing these frequently asked questions and concerns, users can gain a better understanding of amp usage in circular saws and make informed decisions when it comes to selecting and using their tools safely and efficiently.

In the concluding section, we will summarize the key points covered in the article and reiterate the importance of understanding and managing amp usage for optimal performance and safety.

Conclusion

In this comprehensive guide, we have explored the key aspects of amp usage in circular saws. Here are the key points covered:

- Understanding amps and their significance: Amps are a unit of measurement for electrical current and play a crucial role in measuring the power requirements of circular saws.

- Impact of amps on circular saw performance: Higher amp ratings provide increased cutting power and speed, resulting in enhanced efficiency and productivity.

- Determining the amp rating: The amp rating can typically be found on the saw body or in the user manual, and it is important to interpret this information correctly.

- Average amp range for circular saws: Corded circular saws usually fall within the range of 10 to 15 amps, while cordless circular saws have lower amp ratings ranging from 4 to 6 amps, based on the battery voltage.

- Factors affecting amp usage: Blade size and type, material being cut, cutting techniques, and saw motor efficiency can influence the amp usage of a circular saw.

- Importance of using the correct amperage: Using an inadequate power supply can lead to safety risks, decreased performance, motor strain, and potential damage to the circular saw.

- Tips for efficient amp usage: Choosing the right blade, using appropriate speed settings, and properly maintaining the saw and its components can help optimize amp usage.

- Safety precautions and best practices: Wearing protective gear, maintaining a clean and well-lit work area, and following proper handling and cutting techniques are essential for safe operation.

- Frequently asked questions: Addressed common questions and concerns related to amp usage in circular saws, providing detailed explanations and guidance.

It is crucial to understand and manage amp usage for optimal performance and safety. Matching the amp rating of your circular saw with the correct power supply ensures efficient cutting power, reduces the risk of accidents, and prolongs the lifespan of the tool. By following the tips and safety precautions outlined in this article, you can maximize the efficiency and effectiveness of your circular saw while maintaining a safe working environment.

Remember to always consult the manufacturer’s guidelines and instructions specific to your circular saw model for accurate information regarding amp ratings and usage.

Happy and safe cutting!