In this article, we will explore the topic of cutting aluminum with a miter saw. Aluminum is a popular material used in various industries, from construction to automotive, due to its lightweight and corrosion-resistant properties. However, cutting aluminum requires specific tools and techniques to achieve clean and precise cuts. One such tool is a miter saw, which offers versatility and accuracy in cutting different materials, including aluminum.

Using the right tools for cutting aluminum is essential for several reasons. Firstly, aluminum has different properties compared to other materials, such as wood or plastic. It is softer and more prone to heat buildup during cutting, which can lead to blade dulling or even material deformation. Secondly, using improper tools can pose safety risks, as inadequate cutting equipment may cause accidents or damage to the material.

To ensure efficient and effective aluminum cutting, it is crucial to understand the role of a miter saw and how to choose the appropriate blade. Additionally, knowing the proper techniques, safety precautions, and best practices for cutting aluminum with a miter saw will help you achieve optimal results while maintaining a safe working environment.

In the following sections, we will delve into the specifics of cutting aluminum with a miter saw, covering topics such as blade selection, safety measures, cutting techniques, common mistakes to avoid, maintenance tips, and alternative cutting tools. By the end of this article, you will have a comprehensive understanding of how to successfully cut aluminum using a miter saw, empowering you to tackle your aluminum cutting projects with confidence and precision.

Understanding the Basics of Aluminum Cutting

Aluminum is a versatile metal widely used in various industries due to its unique properties. It is lightweight, corrosion-resistant, and exhibits excellent thermal and electrical conductivity. These characteristics make aluminum an ideal choice for applications ranging from aerospace and automotive manufacturing to construction and household products.

However, cutting aluminum presents specific challenges compared to other materials like wood or plastic. Understanding these challenges is crucial for achieving successful cuts. Here are some key considerations:

- Material Properties: Aluminum is a relatively soft metal, which means it is more prone to deformation and surface damage during cutting. It requires careful handling to prevent unwanted bending or warping.

- Heat Buildup: When aluminum is cut, heat can quickly build up due to the material’s high thermal conductivity. This heat can negatively affect both the blade and the aluminum itself. It can lead to blade dulling and reduced cutting efficiency, as well as cause the aluminum to melt or distort.

- Chip Removal: Aluminum tends to generate chips during the cutting process. Unlike sawdust produced when cutting wood, these chips can be sharp and pose safety risks. Proper chip management is essential to maintain a clean and safe working environment.

- Material Clamping: Due to its smooth and slippery surface, aluminum requires secure clamping to prevent movement or vibrations during cutting. Insufficient clamping can result in inaccurate cuts and potentially dangerous situations.

- Surface Finish: Achieving a clean and smooth surface finish is crucial for many aluminum applications. Any imperfections or rough edges resulting from the cutting process may require additional post-cutting steps, such as deburring or sanding, to achieve the desired quality.

By understanding these challenges and implementing the appropriate techniques and precautions, you can overcome the unique characteristics of aluminum and ensure precise and efficient cuts. In the following sections, we will explore the role of a miter saw in aluminum cutting and delve into the specifics of blade selection, safety measures, cutting techniques, common mistakes to avoid, maintenance tips, and alternative cutting tools.

The Role of Miter Saws in Aluminum Cutting

Miter saws are powerful and versatile cutting tools commonly used in woodworking, carpentry, and construction projects. They are designed to make accurate and precise angled cuts, allowing users to create various types of joints, trim, and moldings. However, miter saws are not limited to wood cutting alone. They can also be effectively used for cutting aluminum.

- What is a Miter Saw? A miter saw, also known as a chop saw or a drop saw, consists of a circular blade mounted on a pivoting arm. This arm can be tilted to make angled cuts, while the workpiece is secured on a stationary base. Miter saws are available in different sizes, ranging from compact models for small-scale projects to larger ones for professional use.

- Primary Functions of Miter Saws: Miter saws are primarily designed to make crosscuts, miter cuts (angled cuts along the face), and bevel cuts (angled cuts along the edge) in various materials. With the ability to pivot the blade and adjust the cutting angle, miter saws offer great flexibility for creating precise and complex cuts.

- Versatility for Cutting Aluminum: While miter saws are commonly associated with wood cutting, they can also be used effectively for cutting aluminum. The sturdy construction, powerful motor, and adjustable cutting angles of a miter saw make it well-suited for handling aluminum profiles, bars, or sheets.

Miter saws equipped with the appropriate blade can deliver clean and accurate cuts in aluminum, ensuring the desired dimensions and angles are achieved. Whether you need to cut aluminum for framing, trim work, or custom pieces, a miter saw can provide the necessary precision and control.

It is important to note that not all miter saw blades are suitable for cutting aluminum. Specialized blades designed for non-ferrous metals or aluminum should be used to ensure optimal cutting performance and minimize the risk of blade dulling or material damage.

In the next sections, we will discuss the selection of the right miter saw blade for cutting aluminum, essential safety precautions to follow, proper techniques for cutting aluminum with a miter saw, common mistakes to avoid, and best practices for achieving high-quality results.

Selecting the Right Miter Saw Blade

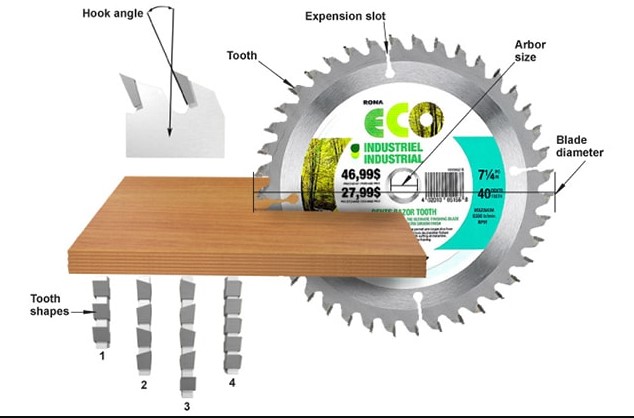

When cutting aluminum with a miter saw, using the correct blade is of utmost importance. The blade selection directly impacts the cutting performance, the quality of the cuts, and the overall efficiency of the process. Here’s what you need to know about choosing the right miter saw blade for aluminum cutting:

- Importance of Using the Correct Blade: Aluminum has unique properties that require a specialized blade for effective cutting. Using the wrong type of blade can result in poor cutting performance, increased blade wear, and potential safety hazards. A blade specifically designed for aluminum cutting ensures cleaner cuts, reduced heat buildup, and improved overall cutting efficiency.

- Different Types of Blades for Aluminum Cutting: There are several types of blades available for cutting aluminum with a miter saw. Here are some commonly used blade types:

- Carbide-Tipped Blades: These blades feature carbide teeth that are specifically designed for cutting non-ferrous metals like aluminum. Carbide-tipped blades are highly durable and can withstand the abrasive nature of aluminum. They provide clean cuts and maintain sharpness for an extended period.

- Aluminum Cutting Blades: These blades are specifically engineered for cutting aluminum and other non-ferrous metals. They often have a special tooth geometry and coatings that help reduce friction, dissipate heat, and prevent chip buildup during cutting. Aluminum cutting blades offer excellent cutting performance and longevity when used for their intended purpose.

- Recommendations based on Thickness and Type of Aluminum: The choice of blade also depends on the thickness and type of aluminum you are cutting. Here are some recommendations:

- Thickness: – For thin aluminum sheets or profiles (up to 1/8 inch or 3mm), a fine-toothed blade with around 80 to 100 teeth is suitable for achieving smooth and accurate cuts. – For thicker aluminum (1/8 inch to 1/2 inch or 3mm to 12mm), a blade with fewer teeth (around 60 to 80) is recommended to handle the material’s increased density.

- Type of Aluminum: – For soft aluminum alloys, such as 6061 or 6063, carbide-tipped blades or aluminum cutting blades are effective choices. – For harder aluminum alloys, such as 7075, consider using specialized blades designed for high-strength metals.

It’s essential to refer to the manufacturer’s recommendations and guidelines for blade selection, as they can provide specific details on blade suitability for different aluminum thicknesses and types.

By using the appropriate blade for your specific aluminum cutting needs, you can ensure cleaner cuts, prolong the blade’s lifespan, and optimize the cutting performance of your miter saw. In the following sections, we will explore essential safety precautions to follow when cutting aluminum, along with proper techniques, common mistakes to avoid, and best practices for achieving precise and high-quality cuts.

Essential Safety Precautions

When working with a miter saw for cutting aluminum or any other material, prioritizing safety is crucial. Miter saws are powerful tools that can cause severe injuries if not used properly. Here are some essential safety precautions to follow:

- Significance of Safety Measures: Safety should always be the top priority when operating a miter saw. By adhering to safety guidelines, you can minimize the risk of accidents, protect yourself, and ensure a safe working environment. Respect the power of the tool and remain attentive throughout the cutting process.

- Wearing Appropriate Safety Gear: To protect yourself while operating a miter saw, it is important to wear the following safety gear:

- Safety Glasses: Wear impact-resistant safety glasses or goggles to protect your eyes from flying debris or chips generated during cutting.

- Hearing Protection: Miter saws can be loud, so wearing hearing protection, such as earplugs or earmuffs, is recommended to prevent hearing damage.

iii. Dust Mask or Respirator: Aluminum cutting can generate fine dust particles, which can be harmful when inhaled. Use a dust mask or respirator to protect your respiratory system.

- Protective Clothing: Wear long sleeves, pants, and closed-toe shoes to protect your skin from accidental contact with the blade or hot aluminum chips.

- Securing the Aluminum Piece: To ensure stability and minimize the risk of accidents, follow these guidelines when securing the aluminum piece for cutting:

- Use Clamps: Securely clamp the aluminum piece to the miter saw’s work surface or a dedicated cutting station. This prevents movement or shifting during the cutting process.

- Support Long Pieces: For long or heavy aluminum pieces, use additional supports or stands to maintain stability and prevent sagging.

iii. Position the Material Correctly: Ensure that the aluminum piece is positioned properly against the fence or the intended cutting area to achieve accurate cuts.

- Maintain Safe Distances: Keep your hands and fingers a safe distance away from the blade during cutting. Avoid placing your hands directly in the path of the blade.

By following these safety precautions and guidelines, you can significantly reduce the risk of accidents and ensure a safe working environment when cutting aluminum with a miter saw. In the next sections, we will delve into the proper techniques for cutting aluminum, common mistakes to avoid, and best practices for achieving high-quality results.

Proper Technique for Cutting Aluminum with a Miter Saw

To achieve clean and precise cuts when working with aluminum using a miter saw, it’s important to follow the proper technique. Here’s a step-by-step guide to help you:

- Setup of the Miter Saw: i. Blade Selection: Install a specialized blade designed for cutting aluminum. Ensure it is securely tightened and aligned with the saw’s arbor.

- Angle Adjustment: Set the miter saw to the desired cutting angle. This can be done by loosening the bevel adjustment knob, tilting the saw’s arm, and tightening the knob once the desired angle is achieved.

iii. Fence Alignment: Adjust the fence of the miter saw to align it with the cutting area. This helps ensure accurate and consistent cuts.

- Cutting Process: i. Secure the Aluminum Piece: Clamp the aluminum piece securely against the fence and work surface of the miter saw. Ensure it is positioned correctly for the intended cut.

- Preparing for the Cut: Before starting the saw, position yourself in a comfortable and safe stance. Ensure there is sufficient clearance around the saw blade.

iii. Start the Saw: Turn on the miter saw and let the blade reach its full speed before initiating the cut.

- Feeding and Controlling the Aluminum Piece: Gently feed the aluminum piece into the rotating blade. Apply a steady and controlled downward pressure to guide the material through the cut. Avoid forcing the aluminum or pushing it too quickly, as it may cause blade binding or inaccurate cuts.

- Maintain a Steady Cutting Pace: It’s important to maintain a consistent cutting pace throughout the process. This helps prevent blade overheating and ensures smooth, clean cuts. Rushing or slowing down abruptly can result in blade deflection or rough cuts.

- Complete the Cut: Allow the blade to complete the cutting motion before releasing the downward pressure. Keep your hands clear of the blade and wait for it to come to a complete stop before removing the cut aluminum piece.

- Tips for Maintaining a Steady Cutting Pace and Avoiding Blade Overheating: i. Use a Suitable Blade: Ensure the blade is designed for aluminum cutting and has the appropriate tooth geometry and coatings to reduce heat buildup.

- Avoid Excessive Feed Rate: Pushing the aluminum piece too quickly can cause the blade to overheat. Maintain a steady and controlled feed rate to allow the blade to cut smoothly without generating excessive heat.

iii. Monitor Blade Temperature: Occasionally touch the blade during cutting to check for excessive heat. If the blade becomes too hot, it’s important to pause and allow it to cool down before resuming cutting.

- Use Lubrication: Applying a lubricant specifically designed for aluminum cutting can help reduce friction and heat buildup. Follow the manufacturer’s instructions for proper lubricant application.

By following these techniques, you can achieve accurate and clean cuts when using a miter saw for cutting aluminum. In the subsequent sections, we will explore common mistakes to avoid, best practices for cutting aluminum, and troubleshooting tips for potential issues that may arise during the cutting process.

Common Mistakes to Avoid

When cutting aluminum with a miter saw, beginners may unknowingly make some common mistakes that can impact the quality of the cuts and pose safety risks. By being aware of these mistakes and taking preventative measures, you can ensure better results. Here are some common mistakes to avoid:

- Improper Blade Selection: Using the wrong blade for cutting aluminum can lead to poor cutting performance, blade dulling, and potential material damage. Avoid using general-purpose or wood-cutting blades. Instead, opt for specialized blades designed for cutting aluminum.

- Insufficient Clamping: Failing to securely clamp the aluminum piece can result in movement or vibrations during cutting, leading to inaccurate cuts or dangerous situations. Always ensure the aluminum piece is firmly secured to the miter saw’s work surface or a dedicated cutting station.

- Excessive Feed Rate: Pushing the aluminum piece too quickly through the blade can cause blade binding, deflection, or rough cuts. Maintain a steady and controlled feed rate, allowing the blade to cut smoothly and efficiently without generating excessive heat.

- Lack of Lubrication: Not using a lubricant designed for aluminum cutting can result in increased friction and heat buildup. Apply an appropriate lubricant to reduce heat and promote smoother cutting. Follow the manufacturer’s instructions for the correct application method.

- Incorrect Cutting Techniques: Inadequate cutting techniques can lead to inaccurate cuts, rough edges, or damage to the aluminum piece. Some common mistakes include improper alignment, incorrect positioning of hands, or using excessive force. Ensure you follow the recommended cutting techniques, maintain a proper stance, and control the aluminum piece carefully.

- Neglecting Safety Precautions: Disregarding safety measures can lead to accidents and injuries. Always wear appropriate safety gear, such as safety glasses, hearing protection, and a dust mask or respirator. Maintain a clear workspace, keep hands away from the blade, and follow safety guidelines for operating the miter saw.

To achieve clean and precise cuts while avoiding these mistakes, consider the following tips:

- Take your time and focus on maintaining a steady cutting pace.

- Double-check the setup of the miter saw, ensuring proper alignment and adjustment.

- Measure and mark the aluminum piece accurately before cutting.

- Use a slow and controlled approach when initiating the cut.

- Regularly monitor the blade temperature and pause if it becomes too hot.

- Inspect the quality of the cuts periodically to ensure accuracy.

- Practice proper blade maintenance and cleaning to optimize performance.

By being mindful of these common mistakes, implementing proper cutting techniques, and prioritizing safety, you can improve the overall cutting experience and achieve clean, precise cuts when using a miter saw for cutting aluminum. In the following sections, we will explore best practices for cutting aluminum, maintenance guidelines, and alternative cutting tools.

Best Practices for Cutting Aluminum

To achieve optimal results when cutting aluminum with a miter saw, it is important to follow best practices that enhance cutting efficiency, accuracy, and safety. Here are some expert tips to help you achieve excellent outcomes:

- Measure and Mark Accurately: Before making any cuts, take the time to measure and mark the aluminum piece accurately. Use precise measuring tools and mark the cutting lines clearly. Double-check your measurements to ensure they align with your desired dimensions. Accurate measurements and markings help you achieve precise cuts and minimize material waste.

- Use Lubricants: Using a lubricant specifically designed for aluminum cutting offers several benefits. Apply the lubricant to the blade and the cutting area to reduce friction and heat buildup. Lubrication helps prolong blade life, improves cutting performance, and reduces the chances of chips or burrs. Follow the manufacturer’s instructions regarding the type and application of the lubricant.

- Optimize Blade Speed and Feed Rate: Finding the right balance between blade speed and feed rate is crucial for achieving clean and precise cuts in aluminum. Adjust the miter saw’s speed and feed rate to a level that allows the blade to cut efficiently without overheating. Experiment with different settings to find the optimal combination for your specific aluminum cutting needs.

- Support Long Aluminum Pieces: When working with long aluminum pieces, additional support is necessary to prevent sagging or bending during the cutting process. Use stands or supports to provide extra stability and maintain a straight cutting line. This ensures accurate and consistent cuts throughout the length of the aluminum piece.

- Minimize Vibration: Excessive vibration can lead to inaccurate cuts and compromise safety. To minimize vibration, ensure the aluminum piece is securely clamped and supported. Additionally, make sure the miter saw is on a stable surface and properly calibrated. Any loose components should be tightened to reduce vibration during cutting.

- Clear the Cutting Area: Keep the cutting area clean and free of debris, chips, or other obstructions. Accumulated debris can interfere with the cutting process, affect the accuracy of the cuts, or create safety hazards. Regularly clear the cutting area and use appropriate chip management techniques, such as vacuuming or sweeping, to maintain a clean workspace.

By implementing these best practices, you can improve the quality of your aluminum cuts, enhance cutting efficiency, and ensure a safer working environment. In the subsequent sections, we will discuss troubleshooting tips for common issues that may arise during aluminum cutting, as well as maintenance guidelines for keeping your miter saw and blade in optimal condition.

Troubleshooting and Maintenance

During the process of cutting aluminum with a miter saw, you may encounter certain issues or challenges. Understanding how to troubleshoot these problems and implementing proper maintenance practices will help you overcome obstacles and maintain the longevity of your miter saw and blade. Here are some troubleshooting tips and maintenance guidelines:

- Potential Issues during Aluminum Cutting: i. Blade Binding: If the blade gets stuck or binds in the aluminum material, immediately turn off the saw and wait for the blade to come to a complete stop. Check for any obstructions, such as misaligned clamps or debris, and remove them before continuing.

- Chipping or Rough Cuts: If you experience chipping or rough edges on the aluminum cuts, it may be due to using an incorrect or worn-out blade. Replace the blade with a suitable one for cutting aluminum. Additionally, ensure a controlled and steady feed rate while cutting to minimize vibrations that can contribute to chipping.

iii. Overheating Blade: Excessive heat can damage the blade and affect cutting performance. If the blade becomes too hot during cutting, pause the operation and allow the blade to cool down. Consider using lubricants specifically designed for aluminum cutting to reduce friction and heat buildup.

- Maintenance Guidelines: i. Blade Cleaning: Regularly clean the miter saw blade to remove any accumulated debris or pitch. Follow the manufacturer’s instructions for cleaning or use specialized blade-cleaning solutions. Ensure the blade is completely dry before reinstalling it.

- Blade Inspection: Periodically inspect the blade for signs of wear, damage, or dullness. If the blade’s teeth are worn or damaged, replace it with a new one. Maintaining a sharp blade is essential for achieving clean and precise cuts in aluminum.

iii. Miter Saw Calibration: Check the calibration of your miter saw regularly to ensure accurate cutting angles and bevels. Follow the manufacturer’s guidelines for adjusting and calibrating the saw as needed.

- Overall Cleaning and Lubrication: Clean the miter saw’s work surface, fence, and other components regularly to remove debris and prevent any buildup that may affect performance. Lubricate the moving parts of the miter saw according to the manufacturer’s recommendations to ensure smooth operation.

- Storage: When not in use, store the miter saw and blade in a dry and protected area to prevent corrosion or damage. Follow the manufacturer’s guidelines for proper storage practices.

By troubleshooting issues promptly and maintaining your miter saw and blade, you can ensure optimal cutting performance, extend the lifespan of your equipment, and achieve consistent, high-quality cuts when working with aluminum. In the final section, we will briefly discuss alternative tools for cutting aluminum, providing a comprehensive understanding of the topic.

Other Tools for Cutting Aluminum

While a miter saw is a versatile tool for cutting aluminum, there are alternative tools available that can also be used for this purpose. Here are some commonly used alternatives:

- Circular Saw: A circular saw equipped with a carbide-tipped or aluminum-cutting blade can be used for cutting aluminum. It offers portability and can handle various cutting tasks. However, it may be less suitable for achieving precise angled cuts compared to a miter saw.

- Bandsaw: Bandsaws can be effective for cutting aluminum, especially when dealing with thicker materials or intricate shapes. They offer greater control and can handle curved cuts. However, bandsaws may have limitations in terms of straight cuts and may require more setup time.

- Plasma Cutter: Plasma cutters are a specialized tool designed for cutting metals, including aluminum. They use a high-temperature plasma arc to melt through the material. Plasma cutters are particularly efficient for thick aluminum sections but may not be suitable for precision cuts or intricate designs.

Comparing these alternatives to a miter saw for cutting aluminum, here are the pros and cons:

- Circular Saw: Pros: Portability, versatility for other cutting tasks, availability. Cons: Less precise for angled cuts, limited cutting depth.

- Bandsaw: Pros: Greater control, suitable for curved cuts, good for thick materials. Cons: Limited straight cutting capacity, setup time, less portable.

- Plasma Cutter: Pros: Efficient for thick aluminum, high cutting speed, minimal heat-affected zone. Cons: Limited precision for fine cuts, specialized tool, may require additional safety precautions.

Emphasizing the Unique Advantages of Using a Miter Saw for Aluminum Cutting:

Using a miter saw for cutting aluminum offers several advantages:

- Precision: Miter saws excel at making precise angled cuts, making them suitable for applications requiring accurate joinery or angled aluminum cuts.

- Versatility: Miter saws can also be used for cutting other materials, such as wood, plastic, or even non-ferrous metals, making them a versatile tool for various projects.

- Ease of Use: Miter saws are relatively straightforward to set up and operate. They provide stability, control, and a fixed cutting platform, ensuring consistent results.

- Speed and Efficiency: With the appropriate blade, miter saws can deliver fast and efficient aluminum cutting, especially for straight cuts and repetitive tasks.

- Wide Availability: Miter saws are commonly found in workshops, making them easily accessible for many users.

While alternative tools have their merits, the unique combination of precision, versatility, ease of use, and efficiency makes a miter saw an excellent choice for cutting aluminum in many applications.

Conclusion

In this article, we have explored the topic of cutting aluminum with a miter saw and provided valuable information to help you achieve successful results. Let’s recap the key points covered:

- Understanding the Basics of Aluminum Cutting: Aluminum has unique properties that require specific techniques and tools for cutting.

- The Role of Miter Saws in Aluminum Cutting: Miter saws are versatile tools known for their accuracy in making angled cuts, and they can also be effectively used for cutting aluminum.

- Selecting the Right Miter Saw Blade: Using a specialized blade designed for aluminum cutting is crucial for achieving clean and precise cuts. Consider the thickness and type of aluminum when choosing the appropriate blade.

- Essential Safety Precautions: Prioritizing safety measures, wearing proper safety gear, and securely clamping the aluminum piece are essential for a safe cutting environment.

- Proper Technique for Cutting Aluminum with a Miter Saw: Following the correct setup of the miter saw, controlling the aluminum piece, and maintaining a steady cutting pace are key to achieving accurate cuts.

- Best Practices for Cutting Aluminum: Measuring and marking accurately, using lubricants to reduce friction, and supporting long pieces are all important practices for optimal aluminum cutting.

- Troubleshooting and Maintenance: Understanding potential issues, such as blade binding or chipping, and implementing regular maintenance practices are essential for resolving problems and prolonging the lifespan of your equipment.

- Unique Advantages of Using a Miter Saw: Miter saws offer precision, versatility, ease of use, and efficiency, making them an excellent choice for cutting aluminum.

It is crucial to use a miter saw correctly and safely when cutting aluminum. Adhering to safety precautions, selecting the right blade, and following proper techniques will help you achieve clean, precise cuts and maintain a safe working environment.

We encourage you to apply the tips, techniques, and best practices discussed in this article to your aluminum cutting projects. With practice and attention to detail, you can successfully accomplish your aluminum cutting goals using a miter saw. Remember to always prioritize safety and refer to manufacturer guidelines for specific instructions.

Happy cutting!