If you’re not familiar with a miter saw, then it’s about time to get to know this powerful tool that is responsible for making clean cuts for all angles. It cuts woods, metals, steel, and other materials quickly through its powerful blade.

However, if you are not able to use the appropriate blade, then your whole machine would not be effective. Most likely, your cuts would not be as clean and fine as the appropriate blades. Remember, there are different types of miter blades out there, each specially created for a purpose. It is just important for you to familiarize these blades so you’ll know which blade are you gonna use for your DIY tasks.

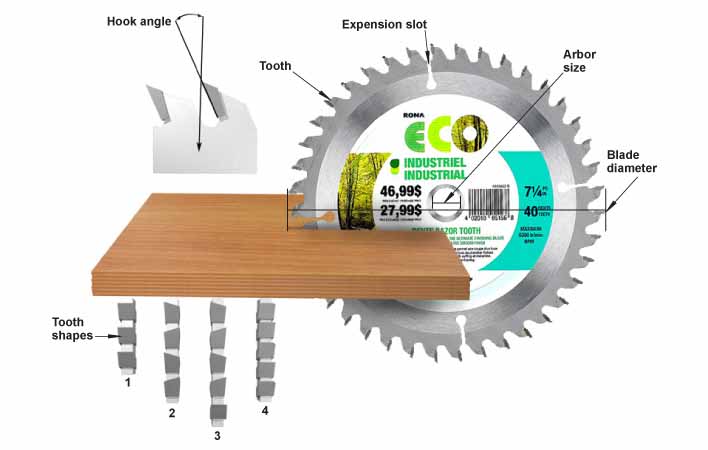

Normally, the size, number of tooth, and unique features are indicated in the blade hence it’s not difficult for you to identify what you are looking for. Of course, it is manufactured by different companies. Each manufacturer has its own unique feature, but the sizes, as well as tooth counts, are more likely the same.

The following are things to consider when choosing the appropriate miter saw blade:

Diameter: Each type of miter saw has a particular size blade that should be used in it. Always check your Miter Saw tool manual. Remember, if you have chosen the wrong blade, you’ll surely encounter problems when you want to cut with your saw.

You can choose among 4 regular sizes of blades:

7-1/2 inches

8-1/2 inches

10 inches

12 inches

Don’t worry. Most miter saws have a built-in warning against the wrong sized blades. When you look at the circular slot in the center of the blade, it usually appears to have different sizes. This means that a 7-1/2 inch blade will not fit with miter saws with different size.

Purpose of the Blade: Consider the things that you want to cut using you’re the miter saw. There are blades specially designed for a specific material. There are also those which are multipurpose. Hence, you have to make sure that the blade you are purchasing is appropriate for the material you will be working on.

Usually, blades come with a specification. So, it wouldn’t be hard for you to choose which one is appropriate. Moreover, you can also ask the sellers about these.

By the way, changing your blades is very easy. You may consider buying spare ones in case the other will get damaged. It’s also advisable to change a new blade before starting a new project.

Tooth Count: The tooth of the blades determines the effective is your blade. A blade with many teeth will surely result in a smoother finish and cleaner cuts than those with lesser teeth. Well, it doesn’t mean that blades with fewer teeth are not good. Blades with few teeth are best in cutting thicker materials.

Moreover, blades with ample teeth are great at cutting plastic. Blades with many teeth could melt the plastic.

Design of Teeth: The blade’s shapes of teeth are additional feature created by each manufacturer. Some blades are just simple, having a triangular shape of teeth while the others are quite customized. Unique shapes of teeth are specially made for cutting hard materials while the simple ones are great at cutting woods.

FAQs

Q1. What is a miter saw?

A1. A miter saw is a powerful tool used to make clean cuts in a variety of materials like wood, metal, and steel.

Q2. What are the different sizes of miter saw blades?

A2. Miter saw blades usually come in four regular sizes: 7–1/2 inches, 8–1/2 inches, 10 inches, and 12 inches.

Q3. What should I consider when choosing a miter saw blade?

A3. You should consider the diameter of the blade, the purpose of the blade, the tooth count, and the design of the teeth.

Q4. How do I know which blade size is appropriate for my miter saw?

A4. Check the miter saw tool manual and make sure the size of the blade fits the slot in the center of the blade.

Q5. Is it important to use the right blade for the right material?

A5. Yes, it is important to use the right blade for the right material in order to get the best results.

Q6. How do I know which blade to use for a particular material?

A6. Each blade usually comes with a specification that indicates the material it is suitable for. You can also ask the sellers for advice.

Q7. Is it important to change the blade before starting a new project?

A7. Yes, it is important to change a new blade before starting a new project.

Q8. What is the difference between blades with many teeth and those with fewer teeth?

A8. Blades with many teeth will result in smoother finish and cleaner cuts while blades with fewer teeth are best for cutting thicker materials.