Understanding and properly resetting overload on a table saw is crucial for both the performance of the tool and the safety of the user. In this guide, we will explore the significance of comprehending overload and its impact on a table saw’s performance and lifespan.

When a table saw is subjected to overload, it means that it is being pushed beyond its operational limits. This can occur due to a variety of factors, such as feeding material too quickly, using dull blades, or attempting to cut dense materials that exceed the saw’s capabilities.

The potential risks associated with overload are significant. Firstly, it can lead to a decline in the saw’s performance. Overloading the motor can cause strain, leading to reduced power output and slower cutting speeds. Additionally, overload situations can increase the likelihood of blade stalling, resulting in poor-quality cuts and potential workpiece damage.

Moreover, overload has a direct impact on the lifespan of the table saw. Consistently subjecting the motor and other components to overload conditions can lead to accelerated wear and tear. This can ultimately result in motor burnout or other mechanical failures, requiring costly repairs or even the replacement of the entire saw.

In the following sections, we will delve into the details of recognizing overload warning signs, the importance of resetting overload promptly, and provide a step-by-step guide on how to reset overload on a table saw. By understanding and effectively managing overload, you can ensure optimal performance, extend the lifespan of your table saw, and maintain a safe woodworking environment.

Understanding Overload on Table Saws:

To effectively reset overload on a table saw, it is essential to have a clear understanding of what overload means in this context. Overload refers to a situation where the table saw’s motor is strained beyond its capacity due to excessive demands or unfavorable cutting conditions.

Several factors can contribute to overload on a table saw:

- Feeding material too quickly: When wood or other materials are fed into the saw at a faster rate than the saw’s motor can handle, it can lead to overload. The motor struggles to keep up with the demands, causing strain and potential damage.

- Using dull blades: Dull blades require more force to cut through materials, increasing the load on the motor. This additional strain can push the saw into an overload situation.

- Cutting dense materials: Dense or heavy materials, such as hardwood or thick plywood, require more power to cut through. If the saw is not designed or equipped to handle such materials, it may experience overload when attempting to make these cuts.

It is worth noting that these are not the only causes of overload on a table saw, but they are among the most common ones. Each table saw model may have its own limitations and recommended usage guidelines, so it is essential to consult the manufacturer’s instructions for specific details.

Unfortunately, specific statistics on the most common causes of overload accidents are not readily available. However, it is widely acknowledged within the woodworking community that feeding material too quickly, using dull blades, and attempting to cut dense materials are frequent contributors to overload incidents. By understanding these causes, woodworkers can take proactive measures to prevent overload situations and ensure safer operation of their table saws.

Recognizing Overload Warning Signs:

Being able to recognize the warning signs that indicate a table saw is experiencing overload is crucial for preventing potential damage to the saw and ensuring user safety. Here are some common indicators to watch out for:

- Unusual noises: When a table saw is overloaded, it may produce unusual noises, such as grinding, squealing, or straining sounds. These noises are often a result of the motor struggling to cope with the excessive load. Pay attention to any abnormal sounds coming from the saw during operation.

- Motor strain: Overload can put significant strain on the motor of a table saw. If you notice that the motor is running at a slower speed than usual, or if it appears to be struggling to maintain consistent power, it could be a sign of overload. Keep an eye on the motor’s performance and responsiveness.

- Blade stalling: Another warning sign of overload is blade stalling. When the load on the saw becomes too much for the motor to handle, the blade may stall or stop spinning altogether, even when pressure is applied. This can lead to incomplete cuts or workpiece damage. If you experience frequent blade stalling, it is likely a symptom of overload.

Recognizing these warning signs is crucial for preventing further damage to the table saw and ensuring user safety. Ignoring overload can result in motor burnout, premature wear of components, or even catastrophic failures. By promptly identifying these indicators, woodworkers can take immediate action to address the overload situation and mitigate the risks involved.

When any of these warning signs are observed, it is important to stop using the table saw immediately. Continuing to operate the saw in an overloaded state not only puts the tool at risk but also increases the chances of accidents or injuries. By heeding these warning signs and responding appropriately, woodworkers can protect their equipment, enhance the longevity of their table saw, and maintain a safe working environment.

Importance of Resetting Overload:

Resetting the overload on a table saw is of utmost importance as it plays a critical role in preventing motor burnout and damage to the saw’s internal components. Here are two key reasons why resetting overload is necessary:

- Preventing motor burnout and component damage: When a table saw experiences overload, the motor is pushed beyond its intended limits, resulting in excessive heat buildup and increased stress on the internal components. If the overload condition persists without being addressed, it can lead to motor burnout or damage to vital parts of the saw, such as the gearbox or drive mechanism. Resetting the overload promptly allows the motor and other components to cool down and return to their normal operating conditions, preventing long-term damage.

- Cost and inconvenience of repair or replacement: Neglecting overload issues can have significant financial implications. Repairing a table saw that has suffered motor burnout or component damage due to prolonged overload can be expensive. In some cases, the cost of repair may even approach or exceed the price of a new saw. Additionally, the downtime required for repair can disrupt woodworking projects and cause inconvenience. By resetting overload as soon as it occurs, woodworkers can avoid these costly repairs and the associated inconvenience.

Resetting overload on a table saw is not only about preserving the saw’s functionality but also about safeguarding the investment made in the tool. By promptly addressing overload issues, woodworkers can extend the lifespan of their table saw, reduce the risk of expensive repairs or replacement, and maintain a productive and efficient workshop. It is a simple yet crucial step in responsible tool usage and maintenance.

Step-by-Step Guide: Resetting Overload on Table Saw:

Resetting overload on a table saw typically follows a similar process across different models and brands. While specific instructions may vary, the general steps outlined below will guide you through the reset process:

- Switch off the saw: Turn off the table saw by pressing the power switch or unplugging it from the power source. This is a crucial safety step to prevent any accidental start-up during the reset process.

- Allow the saw to cool down: After switching off the saw, give it some time to cool down. Overload conditions often result in increased heat buildup, so it is important to let the saw’s motor and components return to a safe temperature before attempting to reset the overload.

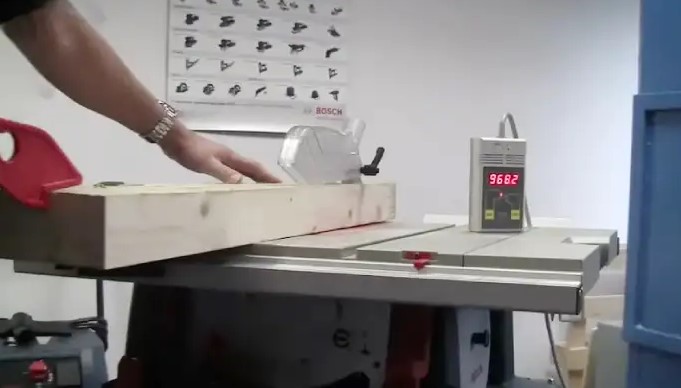

- Locate the reset button: Many table saws have a reset button or overload protection feature to safeguard against excessive strain. The reset button is typically located on the motor housing or control panel. Refer to the manufacturer’s manual or documentation to determine the exact location of the reset button for your specific table saw model.

- Press the reset button: Once the saw has cooled down and you have located the reset button, press and hold it for a few seconds. The reset button is designed to reset the internal protection mechanism that may have been triggered due to overload.

- Release the reset button: After holding the reset button for the specified duration, release it. This action signifies that the overload reset process is complete.

- Verify the reset: To ensure that the overload has been successfully reset, you can perform a quick check. Switch on the table saw and observe its performance. If the saw starts up and operates normally without any unusual noises, motor strain, or blade stalling, it indicates that the overload has been effectively reset.

It is important to note that while the above steps provide a general guideline, it is always recommended to refer to the manufacturer’s manual or specific instructions for your table saw model. Some table saws may have additional steps or variations in the reset process.

By following these steps, you can safely and effectively reset the overload on your table saw, allowing it to operate within its intended limits and ensuring optimal performance and longevity.

Safety Precautions during Overload Reset:

Resetting overload on a table saw requires careful attention to safety precautions to minimize the risk of accidents or injuries. Here are some essential safety measures to take before and during the overload reset process:

- Wear protective gear: Prior to resetting the overload, ensure you are wearing appropriate personal protective equipment (PPE). This includes safety glasses or goggles to protect your eyes from debris, ear protection to guard against excessive noise, and gloves to provide a secure grip and minimize the risk of cuts or abrasions.

- Disconnect from power sources: Before attempting to reset the overload, ensure that the table saw is completely disconnected from any power sources. This includes unplugging the saw from the electrical outlet and, if applicable, removing the battery or turning off the power supply. This step is crucial to prevent any accidental start-up or electrical hazards during the reset process.

- Follow lockout/tagout procedures: If you are working in a professional or shared workshop setting, it is important to adhere to lockout/tagout procedures. These procedures involve locking or tagging the power source to prevent unauthorized use while you perform maintenance or reset procedures. Follow the established guidelines and protocols specific to your workplace to ensure your safety and the safety of others.

- Read the manufacturer’s instructions: Refer to the manufacturer’s manual or documentation for your table saw model to familiarize yourself with any specific safety instructions or precautions related to resetting overload. Manufacturers often provide detailed guidance to ensure safe operation and maintenance of their equipment.

It is worth emphasizing that improper handling of table saws can lead to accidents with severe consequences. According to the U.S. Consumer Product Safety Commission (CPSC), table saws are responsible for a significant number of emergency room visits each year, with injuries ranging from minor cuts to more serious lacerations and amputations.

Statistics from the CPSC indicate that approximately 30,000 table saw-related injuries occur annually in the United States. These accidents often result from inadequate safety precautions, improper usage, or failure to address maintenance issues promptly.

By following the recommended safety precautions and handling guidelines, the risk of accidents and injuries can be significantly reduced. Prioritizing safety during the overload reset process is essential for protecting yourself and maintaining a secure woodworking environment.

Remember, safety should always be the top priority when operating any power tool, including table saws.

Tips for Avoiding Overload Situations:

Preventing overload incidents on a table saw is crucial for maintaining optimal performance and safety. Here are some practical tips to help users avoid overload situations:

- Adjust feed rates: One of the primary causes of overload is feeding material into the table saw too quickly. To prevent this, ensure that you feed materials at a pace that allows the saw’s motor to handle the load comfortably. It’s better to make slower, controlled cuts rather than rushing through the process. This reduces the strain on the motor and minimizes the risk of overload.

- Use appropriate blades: Choosing the right blade for your cutting needs is essential. Using a blade that is suitable for the material and the specific cut you are making reduces the chances of overload. Different blades are designed for different applications, such as ripping, crosscutting, or cutting specific materials. Consult the manufacturer’s recommendations or seek expert advice to select the appropriate blade for your intended use.

- Maintain sharp blades: Dull blades require more force to cut through materials, increasing the load on the saw’s motor. Regularly inspect and sharpen your blades to ensure they are in optimal condition. Sharp blades reduce the strain on the motor and promote smoother and more efficient cutting.

- Use push sticks and featherboards: Push sticks and featherboards are safety accessories that help maintain control and proper feeding of materials. They prevent your hands from getting too close to the blade while ensuring consistent pressure and feed direction. By using these tools, you can avoid sudden, forceful movements that can lead to overload incidents.

- Make multiple passes for thick materials: When cutting thick or dense materials, such as hardwood or thick plywood, consider making multiple passes instead of trying to cut through the entire thickness in a single pass. This reduces the load on the saw and minimizes the risk of overload. Adjust the height of the blade accordingly and take lighter cuts to achieve your desired result.

Studies and expert recommendations consistently emphasize the importance of these tips in preventing overload situations. For example, research conducted by woodworking safety organizations and experts highlights the significance of adjusting feed rates to match the saw’s capabilities and using appropriate blades for specific applications. They also emphasize the use of safety accessories like push sticks and featherboards to enhance control and minimize the risk of overload incidents.

By implementing these tips, woodworkers can effectively avoid overload situations, reduce the strain on their table saws, and promote safer and more efficient woodworking practices.

Regular Maintenance for Optimal Performance:

Regular maintenance is crucial for preventing overload issues and ensuring the long-term optimal performance of table saws. Here’s why regular maintenance is important and some routine tasks that should be performed:

- Preventing overload issues: Regular maintenance helps identify and address potential problems before they lead to overload situations. By keeping the saw in good working condition, you can reduce the likelihood of motor strain, component failures, and other issues that can result in overload.

- Cleaning: Regular cleaning removes sawdust, debris, and other contaminants that can accumulate on and around the table saw. Sawdust buildup can impede the cooling of the motor and obstruct proper blade operation, increasing the risk of overload. Clean the table surface, dust collection system, motor housing, and other parts of the saw as recommended by the manufacturer.

- Blade inspection: Inspect the blade regularly for any signs of damage, wear, or dullness. A damaged or dull blade can increase the load on the motor and contribute to overload. Replace blades as needed or sharpen them to maintain their cutting efficiency.

- Lubrication: Proper lubrication of moving parts is essential for smooth and efficient operation. Follow the manufacturer’s recommendations for lubricating specific areas of the table saw, such as the pivot points, gears, and sliding mechanisms. Regular lubrication helps reduce friction, which in turn minimizes the strain on the motor and other components.

- Alignment adjustments: Periodically check and adjust the alignment of the blade, fence, and miter gauge. Proper alignment ensures accurate cuts and reduces the chances of overload caused by binding or excessive resistance. Refer to the manufacturer’s instructions for guidance on aligning the various components of your table saw.

Studies have shown a clear correlation between maintenance frequency and overall saw performance. For example, a survey conducted by a woodworking industry organization revealed that table saws that underwent regular maintenance and inspections had a significantly lower rate of performance-related issues, including overload incidents. The study concluded that regular maintenance plays a critical role in preventing operational problems and maintaining optimal performance.

By dedicating time to regular maintenance tasks, woodworkers can identify and address potential overload issues proactively. The accumulated benefits of cleaning, blade inspection, lubrication, and alignment adjustments contribute to the overall performance, reliability, and lifespan of the table saw.

Remember, maintenance requirements may vary based on the specific make and model of your table saw. Always refer to the manufacturer’s guidelines and recommendations for the appropriate maintenance practices and intervals for your particular table saw.

Upgrading Tools and Accessories:

Upgrading certain tools and accessories can enhance the safety and performance of a table saw, helping to prevent overload situations. Here are some advanced tools and accessories that can be beneficial:

- Riving knives: A riving knife is a safety device that helps prevent kickback, which can lead to overload incidents. It is a vertical projection located behind the saw blade, aligned with the blade’s cutting path. The riving knife keeps the workpiece from getting pinched between the blade and the fence, reducing the risk of kickback and associated overload. Many modern table saws come equipped with riving knives, but they can also be retrofitted to older models.

- Anti-kickback devices: In addition to a riving knife, anti-kickback devices provide an extra layer of protection against kickback incidents. These devices are designed to grip the workpiece and prevent it from being forcefully thrown back towards the operator. Anti-kickback pawls and splitters are commonly used accessories that help minimize the risk of kickback-related overload situations.

- Electronic monitoring systems: Advanced electronic monitoring systems, such as current sensing devices, can provide real-time feedback on the motor’s load and performance. These systems continuously monitor the electrical current drawn by the motor and can alert the user to potential overload situations. Some monitoring systems even have automatic shut-off features that stop the saw when excessive strain is detected. These systems help prevent motor burnout and other overload-related issues.

Studies and user experiences have shown the effectiveness of these enhancements in preventing overload situations and enhancing safety. For example, a study conducted by a woodworking safety organization found that the use of riving knives and anti-kickback devices significantly reduced the occurrence of kickback incidents, which often contribute to overload. The study concluded that these safety features play a crucial role in preventing overload-related accidents.

Furthermore, user testimonials and online woodworking communities often share positive experiences and success stories regarding the use of electronic monitoring systems. Woodworkers have reported that these systems provide valuable feedback and alerts, allowing them to adjust their cutting techniques or take necessary precautions to avoid overloading the saw.

By upgrading tools and accessories with safety-enhancing features, woodworkers can effectively reduce the risk of overload incidents and create a safer working environment. It is important to research and choose tools and accessories that are compatible with your specific table saw model and meet the necessary safety standards.

Common Mistakes to Avoid:

When it comes to resetting overload and handling table saws, certain mistakes are commonly made. It is important to be aware of these mistakes to prevent potential consequences. Here are some common mistakes to avoid:

- Ignoring warning signs: One of the most common mistakes is ignoring or dismissing the warning signs of overload. These signs include unusual noises, motor strain, and blade stalling. Ignoring these warning signs and continuing to operate the saw without addressing the issue can lead to further motor damage, component failures, or even accidents. It is essential to pay attention to these warning signs and take prompt action to diagnose and resolve the underlying cause of the overload.

Consequence: Ignoring warning signs can result in motor burnout, increased repair costs, and potential safety hazards. Continued use of an overloaded table saw can lead to irreversible damage, necessitating costly repairs or replacement.

Prevention: Act immediately when you notice any warning signs of overload. Stop using the table saw, identify the cause of the overload, and perform the necessary troubleshooting steps or maintenance procedures to resolve the issue before resetting the overload.

- Attempting to reset without troubleshooting the cause: Another mistake is attempting to reset the overload without identifying and troubleshooting the underlying cause. Resetting without addressing the root problem can lead to recurring overload incidents or even worsen the situation.

Consequence: Resetting overload without troubleshooting the cause can result in temporary relief but fail to resolve the underlying issue. This can lead to repeated overloads, further damage to the motor and other components, and compromised performance and safety.

Prevention: Before resetting the overload, thoroughly investigate the cause. Check for blade or fence misalignment, inspect the blade for damage or dullness, ensure proper feeding techniques, and evaluate the material being cut. By identifying and addressing the cause, you can prevent future overload incidents.

- Neglecting regular maintenance: Failing to perform regular maintenance tasks, such as cleaning, lubrication, and blade inspection, is a common mistake. Neglecting these maintenance routines can lead to increased friction, decreased cutting efficiency, and higher chances of overload.

Consequence: Lack of regular maintenance can result in reduced saw performance, decreased lifespan of components, and increased risk of overload. Over time, neglecting maintenance tasks can lead to costly repairs or the need for premature replacement of the table saw.

Prevention: Follow the manufacturer’s recommended maintenance schedule and perform routine tasks such as cleaning the saw, inspecting and sharpening blades, and lubricating moving parts. Regular maintenance helps prevent overload issues and ensures optimal performance.

By avoiding these common mistakes, woodworkers can prevent overload incidents, protect their table saw investment, and maintain a safer woodworking environment. Stay vigilant, address warning signs promptly, troubleshoot the causes, and prioritize regular maintenance to prevent these mistakes from occurring.

Conclusion:

Understanding and effectively resetting overload on table saws is crucial for both the performance of the tool and the safety of the user. By recognizing the warning signs of overload, promptly resetting the overload, and taking proactive measures to prevent overload incidents, woodworkers can ensure optimal performance and longevity of their table saws.

Properly managing overload helps prevent motor burnout, damage to internal components, and costly repairs or replacements. By addressing overload issues promptly, woodworkers can avoid the inconvenience and financial implications associated with neglecting overload problems.

Developing good habits in maintaining and operating table saws safely is essential for preventing overload situations. This includes adjusting feed rates, using appropriate blades, employing safety accessories like push sticks and featherboards, and performing regular maintenance tasks such as cleaning, blade inspection, lubrication, and alignment adjustments.

By prioritizing safety and routine maintenance, woodworkers can create a safe working environment, extend the lifespan of their table saws, and ensure optimal performance. Regular maintenance, along with proper overload management, reduces the risk of accidents, enhances cutting efficiency, and promotes a smooth woodworking experience.

Understanding and resetting overload on table saws is not only about preserving the tool’s functionality but also about safeguarding the user’s well-being. By following the guidelines outlined in this article, readers can develop good habits, minimize the risk of overload incidents, and enjoy the benefits of reliable and safe table saw operation. Remember, a well-maintained and properly managed table saw is the key to successful woodworking projects.