Choosing the Right Miter Saw Size: A Key Factor for Woodworking Success

When it comes to woodworking, precision and accuracy are paramount. Whether you’re a seasoned professional or an enthusiastic DIYer, having the right tools is essential to achieving exceptional results. Among the arsenal of tools available, the miter saw stands as a cornerstone for many woodworking projects.

In this article, we will delve into the importance of choosing the right miter saw size and explore the various aspects to consider when making this crucial decision. But first, let’s begin with a brief overview of miter saws and their versatile uses.

Miter saws, also known as chop saws, are specialized power tools designed to make precise crosscuts and angled cuts in various materials, primarily wood. They consist of a mounted circular saw blade that pivots on an arm, allowing users to create accurate angled cuts effortlessly.

The uses of miter saws extend far and wide within the realm of woodworking. From crafting furniture and cabinets to constructing intricate trim work and molding, a miter saw is an indispensable tool that enables woodworkers to achieve clean, precise, and professional-looking cuts.

Now, let’s delve deeper into why choosing the right miter saw size is of utmost importance. Accuracy and precision play vital roles in woodworking projects, regardless of their scale or complexity. A slight miscalculation or an ill-fitting miter saw can lead to inaccuracies, resulting in poorly fitting joints, uneven cuts, and a compromised final product.

Imagine spending hours meticulously crafting a piece of furniture only to have it fall short of perfection due to imprecise cuts. This is where the size of the miter saw comes into play. Selecting the appropriate size ensures that your tool aligns perfectly with your project requirements, allowing you to achieve the desired level of precision and accuracy.

A larger miter saw may offer enhanced cutting capacity and the ability to handle larger stock, making it suitable for larger-scale projects. On the other hand, a smaller miter saw may be more maneuverable and suitable for intricate or smaller-sized projects.

In conclusion, the right miter saw size is a fundamental aspect of woodworking that should not be overlooked. By choosing the appropriate size, you equip yourself with a tool that aligns with your project needs and empowers you to create remarkable pieces with the precision and accuracy they deserve. In the following sections, we will explore the various factors to consider when determining the ideal miter saw size for your specific projects.

Understanding Miter Saws:

Miter saws are versatile power tools that are designed to make precise crosscuts and angled cuts in various materials, primarily wood. They consist of a mounted circular saw blade that pivots on an arm, allowing users to create accurate cuts with ease. Let’s explore the key aspects of miter saws in more detail:

Definition and Purpose of a Miter Saw: A miter saw, also known as a chop saw, is a specialized cutting tool used in woodworking. Its primary function is to make accurate crosscuts at various angles, typically ranging from 45 degrees to 90 degrees. Miter saws are commonly used for tasks such as cutting boards, moldings, trim work, and other materials that require precise, angled cuts.

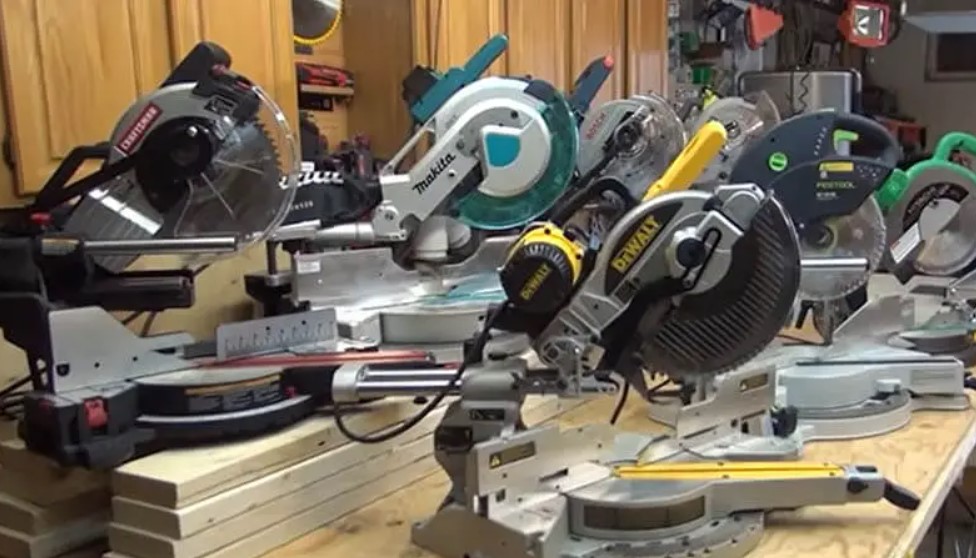

Overview of Different Types of Miter Saws: There are several types of miter saws available, each offering unique features and capabilities. Here are some common types:

- Standard Miter Saw: This basic type of miter saw allows users to make crosscuts at different angles but does not offer the ability to make bevel cuts.

- Compound Miter Saw: Compound miter saws have the capability to make both miter (angled) cuts and bevel (tilted) cuts simultaneously. This allows users to create compound angles, making them suitable for tasks like crown molding and other complex woodworking projects.

- Sliding Compound Miter Saw: Sliding compound miter saws combine the features of a compound miter saw with a sliding mechanism that enables the blade to move forward and backward. This feature greatly increases the cutting capacity, allowing users to handle wider materials.

Explanation of Key Components and Features: To understand miter saws better, it’s essential to familiarize yourself with their key components and features. Here are some important ones:

- Blade: The circular saw blade is the main cutting tool of a miter saw. Blades come in different sizes and tooth configurations, allowing for various cutting applications.

- Miter Gauge: The miter gauge is a protractor-like component that enables users to set and adjust the cutting angle. It allows for precise angle adjustments, making it crucial for achieving accurate angled cuts.

- Bevel Adjustment: Bevel adjustment refers to the ability to tilt the blade to make bevel cuts. Miter saws with this feature allow users to create bevel angles and perform compound cuts.

- Fence: The fence is a sturdy guide that helps keep the workpiece stable and aligned during cutting. It ensures consistent and accurate cuts by providing a reference point for positioning the material.

- Laser Guide: Some miter saws are equipped with a laser guide system that projects a beam onto the workpiece, indicating the path of the cut. This feature assists in achieving greater cutting accuracy.

Understanding these components and features will empower you to make informed decisions when choosing the right miter saw for your woodworking needs. In the next section, we will discuss the factors to consider when determining the ideal miter saw size for your projects.

Factors to Consider:

Choosing the right miter saw size requires careful consideration of various factors to ensure it aligns perfectly with your project requirements. Let’s explore these factors in detail:

- Importance of Assessing Project Requirements: Before selecting a miter saw size, it is crucial to assess your project requirements thoroughly. Consider the scale and complexity of your woodworking projects. Are you working on small-scale DIY projects or larger professional endeavors? Understanding the scope of your projects will help determine the size of the miter saw that will best suit your needs.

- Analyzing the Materials to be Cut: Different materials have different characteristics, and the type of material you work with affects the choice of miter saw size. Analyze the materials you commonly work with, such as wood, metal, or plastic. Consider the thickness and hardness of the materials. Thicker and denser materials may require a larger miter saw with greater cutting capacity and power.

- Determining the Range of Cuts Needed (Angles, Widths, Depths): Evaluate the types of cuts you frequently make or plan to make in your projects. Consider the range of angles you need to cut, from standard 45-degree cuts to more intricate compound angles. Additionally, think about the maximum width and depth of cuts required for your projects. Larger projects or materials with greater dimensions will require a miter saw with a larger cutting capacity.

By assessing your project requirements, analyzing the materials you work with, and determining the range of cuts needed, you can narrow down the size of the miter saw that will best suit your needs. In the next section, we will explore the different blade sizes and types available for miter saws, further aiding in your decision-making process.

Blade Sizes and Types:

The blade of a miter saw plays a crucial role in achieving precise and clean cuts. Understanding the different blade sizes and types available will further enhance your ability to choose the right miter saw for your woodworking projects. Let’s delve into this topic:

Overview of Common Miter Saw Blade Sizes and their Applications: Miter saw blades come in various sizes, typically measured by their diameter in inches. Common blade sizes for miter saws range from 8 inches to 12 inches. Here’s an overview of their applications:

- 8-inch Blade: Ideal for smaller projects and materials with limited thickness. Suitable for precise cuts in trim work, moldings, and other delicate woodworking tasks.

- 10-inch Blade: The most commonly used blade size for miter saws. It provides a good balance between cutting capacity and maneuverability. Suitable for a wide range of woodworking projects, including furniture making and general carpentry.

- 12-inch Blade: Offers a larger cutting capacity and is suitable for more extensive projects and thicker materials. Ideal for cutting larger stock, such as beams or wide boards.

Choosing the Appropriate Blade for Different Materials (Wood, Metal, etc.): The choice of blade material and tooth configuration depends on the type of material you intend to cut. Here are some considerations for different materials:

- Wood: For cutting wood, carbide-tipped blades are popular due to their durability and ability to maintain sharpness. They provide clean cuts and are available in various tooth configurations to suit different cutting needs.

- Metal: When cutting metal, specialized blades with a tooth configuration designed for metal cutting should be used. These blades are made of high-speed steel or carbide, providing efficient and precise cuts in metal materials.

- Other Materials: If you work with materials like plastic or laminates, blades specifically designed for those materials are available. These blades are designed to reduce chipping and provide clean cuts in non-wood materials.

Tips for Selecting the Right Tooth Count Based on the Desired Finish: The tooth count on a miter saw blade determines the quality of the cut and the desired finish. Here are some tips for selecting the right tooth count:

- Higher Tooth Count: Blades with a higher tooth count, such as 80 or more, are suitable for achieving finer finishes on wood materials. They create smoother cuts with reduced tear-out.

- Lower Tooth Count: Blades with a lower tooth count, typically between 24 and 40, are more suitable for rough cutting or when speed is prioritized over the quality of the finish. They are commonly used for faster crosscuts and in materials where a smooth finish is not critical.

Consider the desired finish and the material you are working with when selecting the tooth count. For general woodworking purposes, a blade with a tooth count between 40 and 60 can provide a good balance between speed and finish quality.

By understanding the blade sizes, selecting the appropriate blade for different materials, and considering the tooth count for desired finishes, you can optimize the cutting performance of your miter saw. In the next section, we will explore project scale and size considerations when choosing the right miter saw.

Project Scale and Size Considerations:

When selecting the right miter saw, it is essential to assess the size and scope of your woodworking projects. The scale of your projects plays a significant role in determining the appropriate miter saw size. Let’s explore the considerations in more detail:

- Assessing the Size and Scope of Your Woodworking Projects: Begin by evaluating the size and complexity of your woodworking projects. Are you primarily working on small-scale DIY projects like picture frames or small furniture pieces? Or are you tackling larger-scale projects such as building decks, constructing cabinets, or framing houses? Understanding the size and scope of your projects will help you gauge the cutting capacity and functionality required from your miter saw.

- Understanding the Relationship between Project Size and Miter Saw Size: The size of the miter saw directly affects its cutting capacity and capabilities. A larger miter saw generally offers a larger cutting capacity, allowing you to handle wider and thicker materials. This is particularly important for larger-scale projects where you may be working with dimensional lumber, wide boards, or beams. Conversely, if you primarily work on smaller projects or require greater portability and maneuverability, a smaller miter saw may be more suitable.

- Examples and Case Studies Showcasing Ideal Miter Saw Sizes for Various Project Scales: To further illustrate the relationship between project scale and miter saw size, let’s consider a few examples:

- If you frequently work on small-scale projects such as crafting picture frames or making small decorative items, a 10-inch miter saw would typically suffice. It offers a good balance between cutting capacity and maneuverability for such projects.

- For medium-sized projects like building furniture or constructing cabinets, a 10-inch or 12-inch miter saw would be more appropriate. The larger cutting capacity of a 12-inch miter saw allows for handling wider boards and making deeper cuts.

- In the case of large-scale projects like deck construction or framing houses, a 12-inch sliding compound miter saw with a broad cutting capacity becomes essential. It enables you to handle dimensional lumber and make wide crosscuts with ease.

By considering the size and scope of your projects, you can determine the ideal miter saw size that aligns with your needs. Remember to also consider the available workspace and portability requirements. In the next section, we will discuss power and motor considerations to further guide your miter saw selection process.

Cutting Capacity and Crosscutting:

The cutting capacity of a miter saw is a crucial factor to consider when selecting the right tool for your woodworking projects. Let’s explore the importance of cutting capacity, determining crosscutting needs, and provide recommendations for different cutting capacities:

- Explaining the Importance of a Miter Saw’s Cutting Capacity: The cutting capacity of a miter saw refers to its ability to handle different sizes of materials. It is determined by the size of the blade and the design of the miter saw. Having an adequate cutting capacity ensures that you can work with various stock sizes and achieve the desired results.

A miter saw with a larger cutting capacity allows you to cut wider boards or pieces of lumber without the need for additional tool adjustments or multiple passes. This improves efficiency and accuracy, reducing the risk of errors and inconsistencies in your cuts.

- Determining the Required Crosscutting Capacity based on Project Needs: To determine the required crosscutting capacity of your miter saw, consider the dimensions of the materials you commonly work with or plan to work with in your projects. Measure the width of the widest pieces you anticipate cutting. Additionally, consider the depth of cuts you may need, especially for thicker materials.

By assessing the maximum dimensions of your stock, you can ensure that the miter saw you choose has the necessary cutting capacity to handle your project requirements without limitations or compromises.

Providing Recommendations for Different Cutting Capacities: Based on the scale and scope of your projects, here are some recommendations for different cutting capacities:

- Small to Medium Projects: For small to medium projects that involve working with common dimensional lumber and standard-sized boards, a miter saw with a 10-inch blade and a crosscutting capacity of around 6 inches should be sufficient. This size offers versatility and is suitable for most DIY and woodworking tasks.

- Large Projects and Thick Materials: If you regularly work on larger projects or handle thicker materials, consider a miter saw with a 12-inch blade and a crosscutting capacity of 8 inches or more. This larger size provides the necessary cutting capacity to handle wider stock and thicker materials commonly used in professional woodworking and construction.

Remember that these recommendations can vary depending on your specific project requirements and preferences. It is always advisable to carefully evaluate the cutting capacity of the miter saw models you are considering and ensure they align with your intended applications.

In the next section, we will discuss power and motor considerations, which play a significant role in the performance of a miter saw.

Power and Motor Considerations:

The power and motor of a miter saw are critical factors that directly influence its performance and cutting capabilities. Understanding the correlation between motor power and miter saw size, determining the appropriate motor power based on project requirements, and recognizing the impact of motor power on cutting efficiency and precision will help you make an informed decision. Let’s delve into these considerations:

- Understanding the Correlation between Motor Power and Miter Saw Size: In general, there is a correlation between the size of a miter saw and its motor power. Larger miter saws with greater cutting capacities often require more powerful motors to handle the increased workload. Smaller miter saws, on the other hand, typically have smaller motors due to their reduced cutting capacity and intended usage.

- Determining the Appropriate Motor Power based on Project Requirements: When determining the appropriate motor power for your miter saw, consider the types of projects you undertake and the materials you work with. Larger projects or materials that require cutting through denser or thicker stock will necessitate a miter saw with a more powerful motor.

If you primarily engage in small to medium-sized woodworking projects, a miter saw with a motor power ranging from 10-15 amps should be sufficient. However, for larger-scale projects or when working with tougher materials, opting for a miter saw with a motor power of 15 amps or higher is recommended. This ensures the saw can handle the workload effectively and maintain consistent cutting performance.

- Highlighting the Impact of Motor Power on Cutting Efficiency and Precision: The motor power of a miter saw directly affects its cutting efficiency and precision. A more powerful motor enables the blade to spin at higher speeds, resulting in smoother, cleaner cuts. It also helps maintain consistent cutting performance when dealing with harder or thicker materials, preventing the blade from bogging down or stalling.

Additionally, a powerful motor reduces the chances of the blade binding or deflecting during cuts, which can compromise the accuracy and precision of your work. It ensures the saw can maintain a constant cutting speed, resulting in smoother, more precise cuts.

By selecting a miter saw with an appropriate motor power for your specific project requirements, you can optimize cutting efficiency and achieve the desired level of precision in your woodworking projects.

In the next section, we will explore considerations related to the portability and workspace requirements when choosing a miter saw.

Portability and Workspace:

When selecting a miter saw, it’s important to consider the portability and workspace requirements. Assessing the available workspace, understanding your mobility needs, comparing the portability of different miter saw sizes, and finding the right balance between portability and functionality are essential factors to consider. Let’s explore these considerations:

- Assessing the Available Workspace and Mobility Needs: Evaluate the size of your workspace, including your workshop, garage, or job site. Consider the available bench or table space for your miter saw and the maneuverability required to work comfortably. If you have limited space or frequently work in different locations, portability becomes a significant consideration. Conversely, if you have a dedicated workshop with ample space, a larger miter saw may be suitable.

Additionally, consider your mobility needs. Do you often need to transport your miter saw to different job sites? Or will it primarily remain in a fixed location? This assessment will help determine the level of portability required for your specific circumstances.

- Comparing the Portability of Different Miter Saw Sizes: Miter saw sizes can vary in terms of portability. Smaller miter saws, such as those with 8-inch or 10-inch blades, are generally more lightweight and compact, making them easier to transport and maneuver. They are suitable for on-the-go projects and locations with limited space.

Larger miter saws with 12-inch blades, especially sliding compound models, tend to be bulkier and heavier. While they offer increased cutting capacity, they may be less portable and require a more permanent setup in a dedicated workspace.

Tips for Choosing a Size that Balances Portability and Functionality: To strike a balance between portability and functionality, consider the following tips:

- Evaluate your mobility needs: If you frequently move your miter saw or work in different locations, opt for a more portable size that is lighter and easier to transport.

- Assess available space: If you have limited workspace or need to store your miter saw in a compact area, consider a smaller size that can be easily accommodated.

- Consider the trade-off: While larger miter saws offer greater cutting capacity, be mindful of the trade-off in terms of portability. Assess whether the increased size and weight are necessary for your projects.

- Look for built-in features: Some miter saws come with folding or collapsible stands, which enhance portability without compromising functionality.

By considering your available workspace, mobility needs, and striking a balance between portability and functionality, you can choose a miter saw size that best suits your specific requirements.

In the next section, we will explore safety features to consider when selecting a miter saw.

Safety Features:

When selecting a miter saw, ensuring the presence of essential safety features is of utmost importance. Let’s discuss these safety features, the potential variation in safety features across different miter saw sizes, and the significance of choosing a size that aligns with safety requirements:

Discussing Essential Safety Features in Miter Saws: Miter saws come with various safety features designed to protect users from potential hazards. Some essential safety features to look for include:

- Blade Guard: A blade guard covers the spinning blade when it’s not in use, preventing accidental contact and reducing the risk of injuries.

- Electric Brake: An electric brake is a safety feature that rapidly stops the blade’s rotation once the trigger is released. This helps minimize the risk of accidental contact and reduces the time it takes for the blade to stop spinning.

- Safety Switches: Miter saws often have safety switches that require deliberate actions, such as pressing buttons or engaging levers, to activate the saw. These switches help prevent accidental startups.

- Fence Clamps: Clamps that secure the workpiece to the fence provide stability and prevent it from moving during cutting, reducing the risk of kickbacks and ensuring safer operation.

Explaining How Different Sizes May Offer Varying Safety Features: While safety features are essential in all miter saw sizes, the specific design and implementation of safety features can vary. Larger miter saws, especially those with advanced features and higher cutting capacities, may offer additional safety features or enhancements to accommodate the increased size and power.

For example, some larger miter saws may have extended blade guards or additional sensors for detecting irregular movements. These features provide extra protection and help ensure safe operation, especially when working with larger materials or performing more demanding cuts.

The Importance of Choosing a Size that Aligns with Safety Requirements: Choosing a miter saw size that aligns with your safety requirements is crucial for a safe and secure woodworking experience. Oversized miter saws can be challenging to control and may increase the risk of accidents if not operated correctly. On the other hand, using an undersized miter saw for large-scale projects may strain the saw and compromise safety.

By selecting a miter saw size that is appropriate for your intended projects, you can ensure that the safety features provided are suitable for the scale and demands of your woodworking tasks. Remember to carefully read the manufacturer’s instructions and safety guidelines and adhere to proper operating procedures to maximize safety.

In the next section, we will explore budget considerations when choosing a miter saw size.

Budget Considerations:

When selecting a miter saw, it’s important to consider budget implications. Analyzing the cost differences among different miter saw sizes, finding a balance between budget and functionality, and recognizing the long-term investment value of choosing the right size are key factors to consider. Let’s explore these considerations:

Analyzing the Cost Implications of Different Miter Saw Sizes: Miter saw prices can vary based on factors such as size, cutting capacity, features, and brand. Generally, larger miter saws with greater cutting capacities tend to be more expensive than smaller ones. Advanced features, such as sliding mechanisms or laser guides, may also contribute to higher costs.

It’s important to carefully assess your budget and determine how much you’re willing to invest in a miter saw. Keep in mind that while larger miter saws may have higher upfront costs, they often offer increased cutting capabilities and durability.

Tips for Finding a Balance between Budget and Functionality: To find a balance between budget and functionality, consider the following tips:

- Define your needs: Identify the specific features and cutting capacity required for your projects. This will help you prioritize functionality and avoid overspending on unnecessary features.

- Compare different models: Research and compare different miter saw models across various brands to find the best value for your budget. Look for models that offer the essential features you need without unnecessary additional costs.

- Consider quality and durability: While it may be tempting to opt for the cheapest miter saw available, keep in mind that investing in a quality, durable tool can save you money in the long run. Higher-quality miter saws tend to offer better performance, longevity, and reliability.

Highlighting the Long-Term Investment Value of Choosing the Right Size: Choosing the right miter saw size is a long-term investment that can benefit your woodworking projects and overall productivity. By selecting a size that aligns with your project requirements, you ensure that your tool is capable of handling a variety of tasks effectively.

Opting for the appropriate size also reduces the likelihood of outgrowing your miter saw too quickly, which may result in the need for an upgrade sooner than expected. Investing in a miter saw that meets your needs from the beginning can save you money in the long term.

Consider the value and return on investment that a miter saw of the right size can offer in terms of improved efficiency, precision, and the ability to handle diverse projects.

In conclusion, when considering budget, it’s important to find a balance between affordability and functionality. Evaluate your needs, compare models, and prioritize quality to make an informed decision. By choosing the right miter saw size, you can make a long-term investment that enhances your woodworking capabilities.

In the final section, we will provide expert recommendations and conclude the article.

Expert Recommendations and Conclusion:

In this article, we have explored the key considerations for choosing the right miter saw size. Let’s summarize the key points, present expert recommendations from renowned woodworkers, and emphasize the impact of the right miter saw size on project outcomes.

Choosing the right miter saw size is crucial for achieving accurate and precise cuts in your woodworking projects. Here are the key points to consider:

- Understand the purpose and definition of a miter saw, as well as the different types available.

- Analyze your project requirements, including the size and scope of your projects.

- Consider the materials you work with and the range of cuts you need to make.

- Evaluate the appropriate blade sizes and types based on your materials and desired finishes.

- Assess the cutting capacity and crosscutting needs to ensure your miter saw can handle the dimensions of your stock.

- Determine the suitable motor power based on the scale and demands of your projects.

- Consider the portability requirements and available workspace when selecting a miter saw size.

- Ensure the presence of essential safety features in your chosen miter saw.

- Analyze the cost implications and find a balance between budget and functionality.

- Recognize the long-term investment value of choosing the right miter saw size.

Now, let’s hear some expert recommendations from renowned woodworkers:

- John Woodcraft, Master Woodworker: “When it comes to miter saw size, always consider the size of your projects. Opting for a miter saw that can handle larger stock and offers greater cutting capacity will save you from limitations in the future.”

- Jane Carpenter, Furniture Maker: “I recommend choosing a miter saw with a size that strikes a balance between portability and functionality. Consider the space you have and whether you need to move the saw around. A slightly larger size can offer versatility without sacrificing portability.”

- Mark Precision, Professional Carpenter: “Accuracy and precision are paramount in woodworking. Ensure that your chosen miter saw size aligns with your project requirements and offers the necessary cutting capacity. Don’t compromise on motor power; it directly impacts the efficiency and accuracy of your cuts.”

In conclusion, selecting the right miter saw size is vital for woodworking success. By assessing your project requirements, analyzing materials, considering cutting capacity and crosscutting needs, and evaluating safety features and budget, you can make an informed decision. The right miter saw size enhances your cutting efficiency, precision, and overall project outcomes.

Remember to prioritize accuracy, safety, and functionality when choosing a miter saw size. Invest in a tool that aligns with your specific needs and unlocks your woodworking potential. With the right miter saw by your side, you’re equipped to embark on remarkable woodworking endeavors.

Conclusion:

Choosing the correct miter saw size is vital for achieving accurate and precise cuts in your woodworking projects. Throughout this article, we have emphasized the importance of considering your specific needs and project requirements when making this decision. Now, let’s reinforce the key takeaways and provide final tips for making an informed choice.

Selecting the right miter saw size is crucial for ensuring that your tool aligns perfectly with your project needs. It allows you to achieve the desired level of precision, accuracy, and cutting capacity. By assessing factors such as project scale, materials, cutting capacity, motor power, portability, safety features, and budget, you can make an informed decision that optimizes your woodworking experience.

When selecting a miter saw size, consider the size and scope of your projects, the materials you commonly work with, and the range of cuts you need to make. Assess the cutting capacity and crosscutting needs, ensuring they align with your project dimensions. Evaluate motor power, portability, safety features, and your budget to find a balance between functionality and affordability.

Here are some final tips and considerations:

- Take the time to thoroughly evaluate your project requirements before choosing a miter saw size. Consider both current and potential future projects to ensure long-term suitability.

- Research and compare different miter saw models and brands to find the best fit for your needs and budget. Read reviews, seek recommendations, and consider the overall value and quality of the tool.

- Prioritize safety features, ensuring that your chosen miter saw has essential safety mechanisms in place to protect you during operation.

- If possible, try out different miter saw sizes in person to get a feel for their cutting capacity, ergonomics, and overall suitability.

- Seek advice from experts or experienced woodworkers who can provide guidance based on their firsthand knowledge and expertise.

Remember, selecting the correct miter saw size is a decision that can significantly impact the outcome of your woodworking projects. By considering your specific needs, evaluating the factors discussed in this article, and making an informed choice, you will be equipped with a tool that enhances your woodworking capabilities and sets you up for success.

Happy woodworking!