Understanding the threading direction of table saw blades is crucial for any woodworking enthusiast or professional. It plays a significant role in both the performance and safety aspects of using a table saw. In this article, we will delve into the importance of understanding table saw blade threading direction and explore the potential benefits that reverse threaded blades offer.

When it comes to woodworking, precision and efficiency are key. Table saws are widely used for making precise cuts on various materials, including wood, plastic, and metal. The blade is the heart of a table saw, and its threading direction determines how it interacts with the material being cut.

One of the primary reasons for understanding the threading direction is to ensure proper blade installation. Using a blade with the incorrect threading direction can lead to ineffective cutting, increased wear and tear, and even accidents. By having a clear understanding of how the blade threads onto the arbor, you can ensure that it is securely fastened and aligned for optimal performance.

Now, let’s explore the potential benefits of reverse threaded blades. Reverse threaded blades, also known as left-hand threaded blades, have threads that rotate in the opposite direction compared to standard threaded blades. This means that when the blade is spinning clockwise, the reverse threaded blade will rotate counterclockwise.

The benefits of using reverse threaded blades are twofold. Firstly, they can provide an added level of safety. As the blade rotates in the opposite direction, it can help prevent kickbacks, which are one of the most common causes of table saw accidents. The reverse threading creates a counteracting force that helps keep the workpiece against the table, reducing the risk of it being propelled back towards the operator.

Secondly, reverse threaded blades can offer improved cutting performance in certain applications. The counterclockwise rotation of the blade can enhance the efficiency of cutting certain materials, such as laminates or melamine-coated boards. The reverse threading helps to minimize chipping and tearing, resulting in cleaner cuts and better overall finish.

In conclusion, understanding the threading direction of table saw blades is crucial for both safety and performance. Proper installation and alignment of the blade ensure optimal cutting results, while reverse threaded blades offer added safety measures and can enhance cutting performance in specific applications. In the following sections, we will explore the concept of threaded vs. reverse threaded blades, the purpose of thread direction, and delve into the anatomy of table saw blades to provide a comprehensive understanding of this topic.

Understanding Table Saw Blades:

Table saw blades are essential tools used in woodworking projects to make precise cuts in various materials. They are circular in shape and typically consist of several key components that contribute to their cutting performance. Let’s take a closer look at table saw blades and their role in woodworking:

Components of Table Saw Blades: Table saw blades are composed of the following components:

- Blade Body: The blade body refers to the circular disc of the blade, usually made of high-quality steel or carbide. It provides stability and support during the cutting process.

- Teeth: The teeth are the sharp cutting edges located along the circumference of the blade. They are responsible for removing material as the blade rotates.

- Gullet: The gullets are the spaces between the teeth. They act as channels to remove the sawdust and debris generated during cutting, preventing clogging and ensuring smooth operation.

- Expansion Slots: These are thin slots or cuts in the blade body that help dissipate heat and reduce the risk of warping due to high temperatures generated during prolonged use.

Types of Table Saw Blades: Various types of table saw blades are available in the market, each designed for specific cutting applications. Some common types include:

- Rip Blades: Rip blades have fewer teeth and larger gullets, making them ideal for cutting along the grain of the material, such as ripping boards or planks.

- Crosscut Blades: Crosscut blades have more teeth and smaller gullets, allowing them to produce clean cuts across the grain of the material.

- Combination Blades: Combination blades, as the name suggests, are versatile options that can handle both ripping and crosscutting tasks. They have a mix of teeth designed for efficient cutting in various directions.

- Dado Blades: Dado blades consist of multiple stacked blades or chippers used to create wider grooves or dado cuts for joinery purposes.

- Specialty Blades: There are also specialty blades available for specific woodworking applications, such as laminate-cutting blades, plywood blades, and melamine blades.

It’s important to select the appropriate type of blade based on the specific woodworking task at hand. Choosing the right blade will ensure clean cuts, minimize tear-out, and enhance overall efficiency.

Understanding the different components and types of table saw blades is crucial for selecting the right blade for your woodworking projects. In the following sections, we will explore the concept of threaded vs. reverse threaded blades, the purpose of thread direction, and delve into the anatomy of table saw blades to provide a comprehensive understanding of this topic.

Threaded vs. Reverse Threaded:

Understanding the concept of threaded and reverse threaded fasteners is essential when discussing table saw blades. Fasteners, such as bolts, screws, and nuts, utilize threads to join and secure materials together. Let’s explore the concept of threaded and reverse threaded fasteners, as well as their applications in various industries:

Threaded Fasteners: Threaded fasteners are widely used in numerous industries and applications. They consist of a helical ridge, known as a thread, that winds around the fastener’s shank. This thread allows for a rotational motion when tightening or loosening the fastener. When threaded fasteners are tightened, the threads engage with the corresponding threads of a mating component, creating a secure and tight connection.

Common applications of threaded fasteners include:

- Construction Industry: Threaded fasteners, such as bolts and screws, are extensively used in construction for assembling structures, joining structural elements, and securing various components.

- Automotive Industry: Threaded fasteners play a vital role in vehicle assembly, holding together various parts such as engine components, chassis elements, and body panels.

- Aerospace Industry: Aerospace applications rely heavily on threaded fasteners to ensure the integrity and safety of aircraft structures, including wings, fuselages, and control surfaces.

- Manufacturing Industry: Threaded fasteners are used in manufacturing processes for equipment assembly, machinery construction, and product fabrication.

Reverse Threaded Fasteners: Reverse threaded fasteners, also known as left-hand threaded fasteners, have threads that rotate in the opposite direction compared to standard threaded fasteners. While standard threaded fasteners tighten by turning clockwise, reverse threaded fasteners tighten when turned counterclockwise.

Applications of reverse threaded fasteners include:

- Specialized Machinery: Reverse threaded fasteners are used in specific machinery or equipment where counterclockwise tightening is necessary to prevent unintentional loosening due to the machine’s rotational motion.

- Stabilizing Devices: Reverse threaded fasteners find applications in devices where vibrations or other forces might cause regular threaded fasteners to loosen. By rotating in the opposite direction, reverse threaded fasteners provide added resistance to prevent unintentional loosening.

- Safety Equipment: Certain safety equipment, such as bicycle pedals or circular saw blade nuts, may incorporate reverse threaded fasteners to minimize the risk of accidental loosening during use.

It’s important to note that while reverse threaded fasteners have their specific applications, they are not as commonly used as standard threaded fasteners in most industries.

Understanding the differences between threaded and reverse threaded fasteners helps us appreciate the importance of threading direction in various applications. In the next section, we will discuss the purpose of thread direction specifically in relation to table saw blades and its impact on cutting performance.

The Purpose of Thread Direction:

The thread direction plays a significant role in the functionality and performance of various tools and equipment, including table saw blades. Understanding the purpose of thread direction is crucial to ensure proper operation and optimize cutting performance. Let’s explore the significance of thread direction and how it affects the cutting performance of table saw blades:

Significance of Thread Direction: Thread direction serves several important purposes in tools and equipment that utilize threaded components. The primary purposes include:

- Secure Fastening: The thread direction allows for the tightening and secure fastening of threaded components. When the threads of two mating components engage in the same direction, rotating one component clockwise causes the threads to mesh and tighten the connection.

- Preventing Loosening: Thread direction helps prevent unintentional loosening of fasteners due to external forces or vibrations. The threaded engagement resists rotational forces that would otherwise cause the fastener to unscrew. This is particularly important in tools and equipment where stability and safety are critical.

- Uniform Rotation: Thread direction ensures consistent and uniform rotation of components when applying torque. This allows for smooth operation and avoids undue stress on the threaded connections.

Impact on Cutting Performance of Table Saw Blades: In the context of table saw blades, the thread direction of the arbor nut that secures the blade onto the saw’s arbor directly impacts the cutting performance. The correct thread direction ensures the blade remains securely in place during operation. Here’s how thread direction affects the cutting performance:

- Secure Blade Installation: Using the correct thread direction on the arbor nut ensures proper installation and secure fastening of the blade onto the arbor. This is crucial for maintaining stability and alignment during cutting tasks, preventing wobbling or shifting that can lead to inaccurate cuts and potential safety hazards.

- Avoiding Unintentional Loosening: The thread direction helps prevent the arbor nut from loosening during operation. The rotational motion of the blade generates significant forces, including vibration and centrifugal forces. By employing the appropriate thread direction, the arbor nut resists these forces, ensuring the blade remains securely in place throughout the cutting process.

- Stability and Cut Quality: When the blade is securely fastened with the correct thread direction, it maintains stability and minimizes vibrations. This stability enhances the precision and accuracy of the cuts, resulting in cleaner edges, reduced tear-out, and overall improved cut quality.

In summary, the thread direction in tools and equipment, including table saw blades, serves the purpose of secure fastening, preventing unintentional loosening, and enabling uniform rotation. Understanding and utilizing the correct thread direction for table saw blade installation is crucial for maintaining stability, optimizing cutting performance, and ensuring both safety and precision in woodworking tasks.

In the next section, we will delve into the anatomy of table saw blades, providing a detailed explanation of their different parts and how they contribute to the cutting process.

Table Saw Blade Anatomy:

To understand how the threading direction influences the operation of a table saw blade, it’s essential to have a clear understanding of the different parts that make up the blade. Here’s a detailed explanation of the various components of a table saw blade and how the threading direction impacts its operation:

- Blade Body: The blade body refers to the circular disc of the blade. It is typically made of high-quality steel or carbide. The blade body provides stability and support during the cutting process. It also houses the other critical components of the blade.

- Teeth: The teeth are the sharp cutting edges located along the circumference of the blade. They are responsible for removing material as the blade rotates. The design and configuration of the teeth can vary depending on the type of cut the blade is designed for, such as ripping or crosscutting. The teeth engage with the workpiece, removing material and creating the desired cut.

- Gullet: The gullets are the spaces between the teeth. They act as channels to carry away the sawdust, chips, and debris generated during cutting. Proper chip evacuation is crucial to prevent clogging, overheating, and poor cutting performance. The size and shape of the gullets impact the efficiency of debris removal.

- Expansion Slots: Expansion slots are thin slots or cuts in the blade body. They are typically located near the blade’s center and run outward towards the perimeter. These slots help dissipate heat generated during cutting and reduce the risk of warping or distortion due to thermal expansion. They also aid in noise reduction and improve overall blade performance.

Now, let’s discuss how the threading direction influences the operation of the blade:

- Blade Installation: The threading direction of the arbor nut on the table saw determines how the blade is installed and secured onto the arbor. The blade’s threading direction must match that of the arbor nut to ensure a proper and secure fit. Correct installation ensures stability and prevents the blade from loosening during operation, which could lead to accidents or poor cutting results.

- Stability and Performance: When the blade is securely fastened with the correct threading direction, it maintains stability and minimizes vibrations. This stability is crucial for precise and accurate cuts. Vibrations or blade movement can result in poor cut quality, increased tear-out, and potential safety hazards. The threading direction ensures that the blade remains securely in place, allowing for smooth and controlled cutting operations.

- Safety Considerations: The threading direction of the blade’s arbor nut also plays a role in safety. In the case of reverse threaded blades, the counterclockwise rotation created by the reverse threading can provide added safety by countering the forces that could lead to kickbacks. This helps keep the workpiece against the table and reduces the risk of the material being propelled back towards the operator.

Understanding the different parts of a table saw blade and how the threading direction influences its operation is crucial for proper blade installation, stability, and overall cutting performance. In the next section, we will explore the characteristics and applications of standard threaded table saw blades and reverse threaded blades, highlighting their respective benefits and limitations.

Standard Threaded Table Saw Blades:

Standard threaded table saw blades are the most commonly used type of blades in woodworking. They have threads that rotate in the standard clockwise direction during operation. Let’s discuss the characteristics, advantages, and common applications of standard threaded table saw blades:

Characteristics of Standard Threaded Blades:

- Thread Direction: Standard threaded blades have threads that rotate in a clockwise direction when the blade is spinning. This aligns with the direction of rotation of most table saws, ensuring proper operation and secure fastening.

- Cutting Performance: Standard threaded blades are versatile and suitable for a wide range of cutting tasks. They provide reliable and efficient cutting performance for general-purpose woodworking applications.

Advantages of Standard Threaded Blades:

- Wide Availability: Standard threaded table saw blades are readily available in various sizes, tooth configurations, and materials. They are manufactured by numerous reputable brands, making them easily accessible for woodworkers.

- Compatibility: Standard threaded blades are compatible with the majority of table saw models, ensuring a wide range of options for users.

- Versatility: Standard threaded blades are designed to handle different types of cuts, including ripping and crosscutting. They are suitable for cutting various materials, such as solid wood, plywood, and composite boards.

Common Applications of Standard Threaded Blades:

- General Woodworking: Standard threaded blades are widely used in general woodworking tasks, including cutting boards, panels, and solid wood for various projects.

- Construction and Carpentry: These blades are commonly employed in construction and carpentry projects for tasks like framing, building structures, and installing wood flooring.

- Furniture Making: Standard threaded blades are frequently utilized in furniture making for cutting and shaping wood components, joinery, and precise cuts on different furniture pieces.

- Cabinet Making: Cabinet makers rely on standard threaded blades for various cutting tasks involved in cabinet construction, such as cutting panels, dados, and rabbets.

- Home DIY Projects: Standard threaded blades are also popular among hobbyists and DIY enthusiasts who undertake small woodworking projects at home, such as building shelves, crafting decorative items, or making repairs.

Standard threaded table saw blades offer versatility, compatibility, and wide availability, making them suitable for a broad range of woodworking applications. However, it’s important to choose the appropriate tooth configuration and blade material based on the specific cutting requirements and material being worked on.

In the next section, we will explore reverse threaded table saw blades, highlighting their unique benefits, applications, and considerations when using them.

Reverse Threaded Table Saw Blades:

Reverse threaded table saw blades, also known as left-hand threaded blades, are blades with threads that rotate in the counterclockwise direction when the blade is spinning. These blades offer unique benefits in terms of safety and performance. Let’s delve into the concept of reverse threaded table saw blades and explore their advantages:

Concept of Reverse Threaded Blades: Reverse threaded blades are designed with threads that rotate in the opposite direction compared to standard threaded blades. When the blade spins clockwise, the reverse threaded blade rotates counterclockwise. This reverse threading creates a unique cutting motion that offers distinct advantages in certain woodworking applications.

Benefits of Reverse Threaded Blades:

- Enhanced Safety: One of the primary benefits of reverse threaded blades is increased safety. The counterclockwise rotation counteracts the natural tendency of the blade to lift the workpiece, reducing the risk of kickbacks. Kickbacks occur when the workpiece is propelled backward toward the operator, which can cause serious injuries. The reverse threading helps keep the workpiece pressed against the table, minimizing the likelihood of kickbacks and improving overall operator safety.

- Improved Stability: Reverse threaded blades provide enhanced stability during cutting operations. The counterclockwise rotation helps maintain better control over the workpiece, resulting in smoother and more controlled cuts. This stability is particularly advantageous when working with delicate or highly-figured materials that are prone to tear-out or splintering.

- Cleaner Cuts: Reverse threaded blades can produce cleaner cuts in certain materials. The counterclockwise rotation helps to minimize chipping and tearing, especially on materials like laminates or melamine-coated boards. The reverse threading motion allows for a more controlled and precise cutting action, resulting in smoother edges and improved cut quality.

- Specific Applications: Reverse threaded blades are commonly used in specialized woodworking tasks that require a specific cutting motion. For example, they are often employed in cutting certain types of veneers, delicate hardwoods, or materials that are prone to splintering. The reverse threading helps mitigate the risk of damage or tear-out that can occur with standard threaded blades.

It’s important to note that reverse threaded blades are not typically used for general woodworking applications. Their specific benefits and applications are more niche, catering to particular cutting requirements and materials.

When using reverse threaded blades, it’s crucial to ensure that the threading direction matches the arbor nut and the table saw’s specifications. Proper installation and alignment of the blade are essential to maintain safety, stability, and optimal cutting performance.

In the following sections, we will explore the pros and cons of reverse threaded blades, provide tips for choosing the right blade, and offer best practices for using table saw blades effectively.

Pros and Cons of Reverse Threaded Blades:

Using reverse threaded blades offers unique advantages in specific woodworking applications. However, it’s important to consider both the benefits and limitations before incorporating them into your cutting tasks. Here’s an objective assessment of using reverse threaded blades:

Pros of Reverse Threaded Blades:

- Enhanced Safety: Reverse threaded blades provide an added level of safety by counteracting the lifting force that can lead to kickbacks. This can help prevent accidents and ensure a safer working environment.

- Improved Stability: The counterclockwise rotation of reverse threaded blades enhances stability during cutting. This can result in smoother, more controlled cuts, especially when working with delicate materials or making precise cuts.

- Cleaner Cuts: Reverse threaded blades can produce cleaner cuts, particularly in materials that are prone to chipping or splintering. The reverse motion helps minimize tear-out and improve the overall cut quality.

- Specific Applications: Reverse threaded blades are ideal for specific woodworking tasks that require a counterclockwise cutting motion, such as working with certain veneers, delicate hardwoods, or materials with fragile surfaces.

Cons of Reverse Threaded Blades:

- Limited Availability: Reverse threaded blades may not be as readily available as standard threaded blades. They might have a more specialized market and be offered by fewer manufacturers or suppliers.

- Reduced Versatility: Reverse threaded blades are not suitable for general woodworking applications. Their specific threading direction limits their versatility, and they may not perform as effectively in tasks that require standard threaded blades.

- Learning Curve: Using reverse threaded blades may require some adjustment in technique and familiarity with the counterclockwise cutting motion. Operators accustomed to standard threaded blades may need to adapt their approach to achieve optimal results.

- Compatibility: It’s important to ensure that your table saw and arbor nut are compatible with reverse threaded blades. Not all table saws are designed to accommodate reverse threaded blade installation.

Considering these pros and cons, the use of reverse threaded blades can be advantageous in specific scenarios where safety, stability, and clean cuts are of utmost importance. However, they are not intended as a replacement for standard threaded blades, which are more versatile and widely used in general woodworking applications.

In the following sections, we will provide tips for choosing the right blade based on your specific needs and offer best practices for using table saw blades effectively, ensuring optimal performance and longevity.

Choosing the Right Blade for Your Needs:

Selecting the appropriate table saw blade is crucial for achieving desired results in your woodworking projects. Consider the following tips when choosing a blade for specific tasks:

- Determine the Material Type: Different materials require different types of blades. Consider the type of material you will be working with, such as solid wood, plywood, MDF, or laminate. Each material may have specific blade requirements to ensure clean cuts and minimize tear-out.

- Consider the Cut Quality: Evaluate the desired cut quality for your project. If you need clean and smooth cuts, choose blades with a higher tooth count. Blades with more teeth result in finer cuts, while blades with fewer teeth are better suited for rough cuts.

- Match Blade Type to Task: Identify the specific cutting task you need to accomplish, such as ripping or crosscutting. Select a blade that is designed for that particular task. Rip blades are optimized for cutting along the grain, while crosscut blades are better suited for cutting across the grain.

- Tooth Configuration: Consider the tooth configuration that suits your needs. Alternate top bevel (ATB) blades are versatile and provide clean cuts, while flat top (FT) blades are better for ripping. Combination blades offer a mix of ATB and FT teeth, making them suitable for general-purpose cutting.

- Blade Coating and Material: Blades can have different coatings and materials to enhance their performance. Carbide-tipped blades are known for their durability and longevity. Additionally, coatings like titanium nitride (TiN) or carbide impregnation can reduce friction, resulting in smoother cuts and extended blade life.

- Thread Direction: Take note of the threading direction required for your table saw. Most table saws use standard threaded blades. However, if you’re considering a reverse threaded blade for specific applications, ensure your table saw and arbor nut are compatible.

- Consult Manufacturer Recommendations: Refer to the manufacturer’s recommendations and specifications for your table saw. They often provide guidance on the appropriate blade types, sizes, and thread directions for optimal performance and safety.

- Budget Considerations: Consider your budget when selecting a blade. Higher-quality blades often offer better performance and durability but can be more expensive. Evaluate your needs and balance them with your budget to find the best blade option.

By considering these factors, you can choose the most suitable table saw blade for your specific woodworking tasks. Remember to prioritize safety, cut quality, material compatibility, and threading direction to ensure the best results.

In the following section, we will provide best practices for using table saw blades effectively, including maintenance, cleaning, and handling tips to prolong their lifespan and ensure safe operation.

Best Practices for Using Table Saw Blades:

To ensure safe and effective use of table saw blades and extend their longevity, follow these best practices:

Safe Blade Usage:

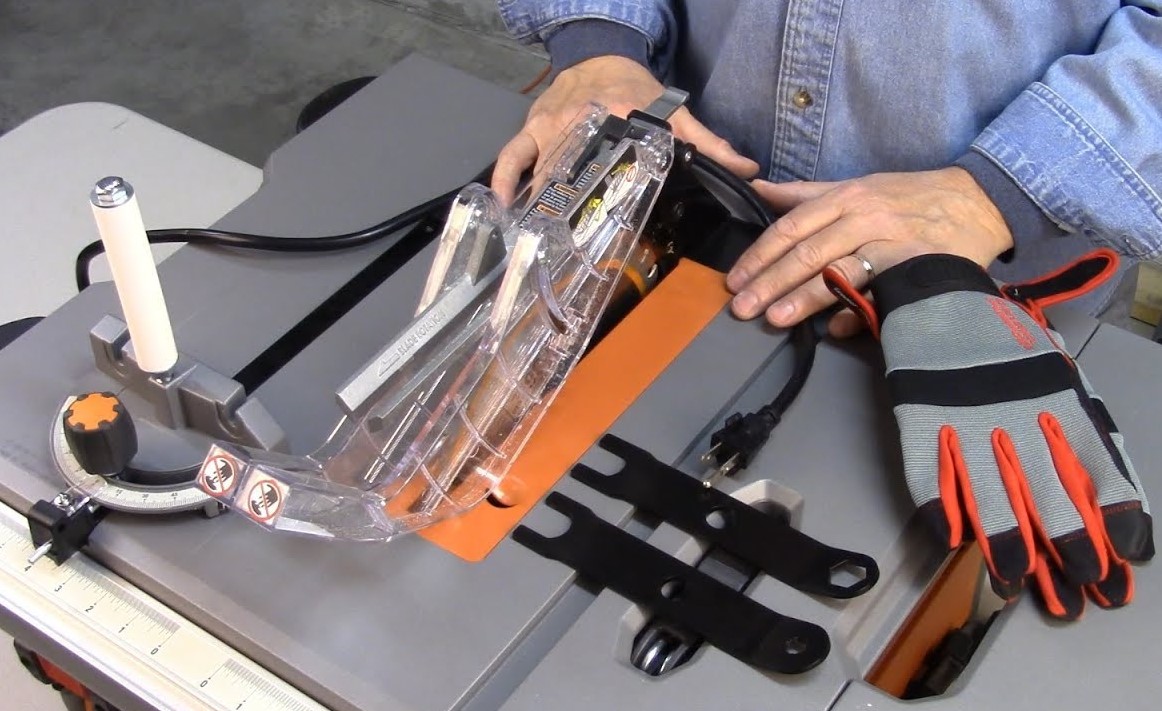

- Always wear appropriate personal protective equipment (PPE), including safety glasses, ear protection, and a dust mask, to protect yourself from potential hazards.

- Ensure the table saw is properly set up and adjusted before using the blade. Follow the manufacturer’s instructions for aligning the blade, fence, and miter gauge.

- Use a blade guard and riving knife whenever possible to prevent kickbacks and ensure operator safety.

- Feed the material smoothly and consistently through the blade, avoiding excessive force or pushing. Maintain a firm grip on the workpiece and use push sticks or push blocks when necessary.

- Avoid overloading the blade by attempting to cut material that exceeds the blade’s capacity. Refer to the blade’s specifications for maximum cutting depth and material thickness.

Maintenance and Cleaning:

- Regularly inspect the blade for signs of damage, such as chipped or worn teeth. Replace blades that show excessive wear or damage to maintain optimal cutting performance.

- Clean the blade after each use to remove resin, pitch, and sawdust buildup. Use a blade cleaning solution or a mild household detergent along with a stiff brush or a dedicated blade cleaning tool. Rinse thoroughly and dry completely before storing.

- Lubricate the arbor regularly to prevent rust and ensure smooth rotation. Use an appropriate lubricant recommended by the manufacturer.

- Store blades properly in a dedicated blade case or blade rack to protect them from damage and maintain their sharpness.

Handling and Transport:

- Handle blades with care, keeping your hands away from the sharp teeth and edges. Use gloves or blade handling tools when necessary to minimize the risk of cuts or injuries.

- When transporting blades, ensure they are securely packaged or stored in protective cases to prevent damage to the teeth and cutting edges.

- Avoid dropping or mishandling blades, as it can result in deformation or damage that affects their performance.

- When changing blades, ensure the table saw is unplugged and the blade has come to a complete stop. Follow proper procedures for blade removal and installation, referring to the manufacturer’s instructions.

By following these best practices, you can ensure safe and effective use of table saw blades while extending their lifespan. Regular maintenance, cleaning, and proper handling contribute to better cutting performance and a safer woodworking environment.

In conclusion, understanding and adhering to safe blade usage practices, along with proper maintenance and handling, are essential for optimal performance, longevity, and safety when working with table saw blades.

Conclusion:

In this article, we explored the topic of table saw blades and their threading direction. Here are the key points to summarize:

- Understanding the threading direction of table saw blades is crucial for optimal performance and safety in woodworking projects.

- Table saw blades consist of various components, including the blade body, teeth, gullets, and expansion slots.

- Standard threaded blades are the most commonly used type and offer versatility for general woodworking tasks.

- Reverse threaded blades rotate counterclockwise and provide benefits such as enhanced safety, improved stability, and cleaner cuts in specific applications.

- The threading direction of the arbor nut influences blade installation, stability, and overall cutting performance.

- Factors to consider when choosing a blade include material type, desired cut quality, tooth configuration, blade coating and material, and thread direction.

- Best practices for using table saw blades include following safety guidelines, performing regular maintenance and cleaning, and proper handling and storage.

- Understanding and adhering to safe blade usage practices are crucial for both optimal performance and operator safety.

In conclusion, understanding the threading direction of table saw blades is of utmost importance. It ensures proper installation, stability, and optimal cutting performance. Whether using standard threaded blades for general woodworking tasks or considering the benefits of reverse threaded blades for specific applications, prioritizing safety, selecting the appropriate blade, and following best practices will contribute to successful woodworking projects and a safe working environment.